In the world of modern manufacturing, everything is accurate. Whether you are shaping optical glass, cutting sapphire, or working with quartz, you need a machine that can give smooth, accurate cuts every time. This is the place where the vertical diamond wire cutting machine comes. It is one of the most advanced devices for cutting rigid and brittle material with extreme accuracy. The diamond wire saw for vertical cutting uses a great diamond-coated wire to slice through the material without cracks, chips, or deformation. Due to its accuracy and efficiency, it is trusted by industries such as optics, photonics, semiconductor manufacturing and scientific research.

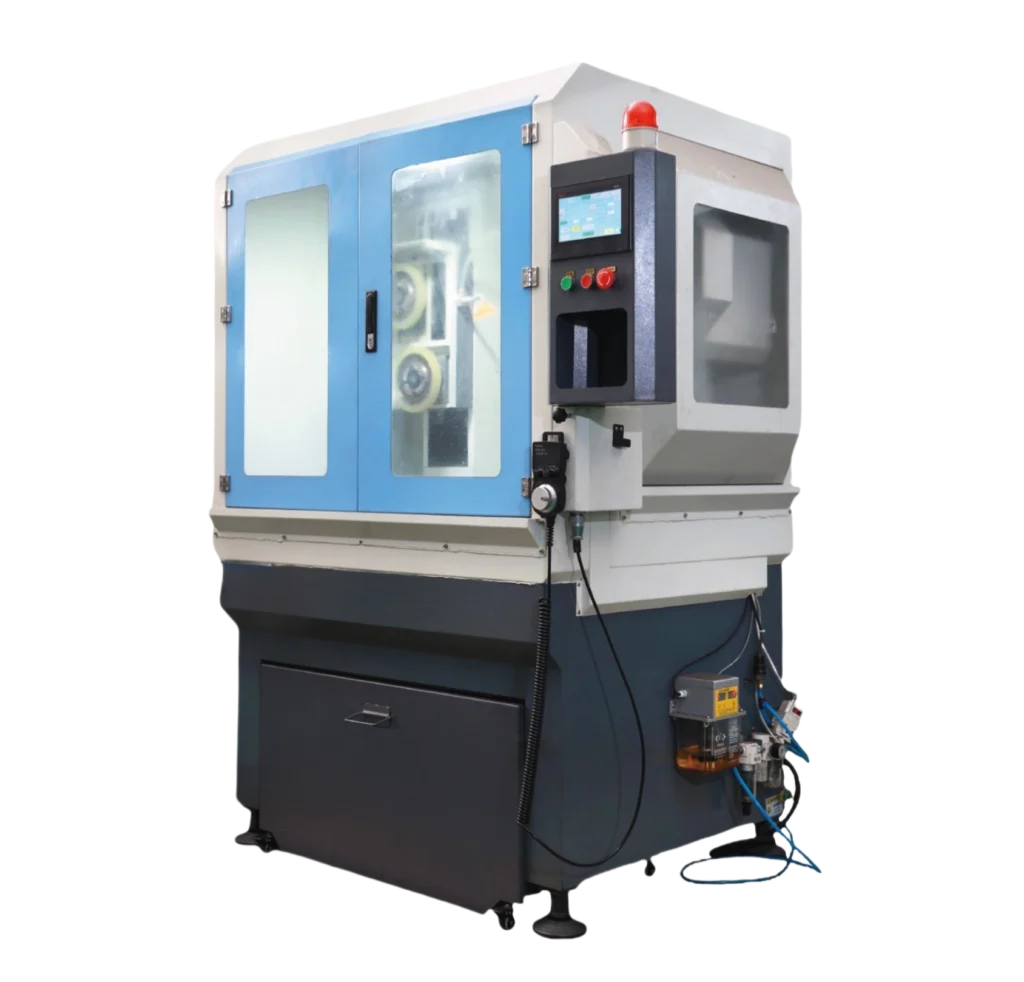

Smart vertical wire cutting machine – SGSM 40

SGSM 40 oscillation wire glass slices is a strong and smart vertical diamond wire cutting machine.

It is designed to cut hard and brittle materials such as sapphire, quartz, alumina and ceramic. The machine uses a vertical wire that goes up and down while cutting. This speed acts like a cutting and polishing process in a step. The result is a smooth surface with very little snatch.

This precision vertical cutting machine can handle large blocks up to 400 × 400 × 400 mm in size. Its strong gentry frame keeps everything stable, so every cut is straight and accurate. The full cover keeps the dust inside and makes the work area safe and clean.

You can control everything with an easy touchscreen or handheld remote. You can proceed to wire speed, swing speed, and table. The high-speed wire can reach 38 meters/second, which means sharp and smooth cuttings.

Vertical Diamond Wire Cutting Machines Working Principle

The function of a vertical diamond wire cutting machine is simple but very effective. The Industrial diamond wire cutting system uses a very thin wire coated with industrial diamonds. This wire is looped around a set of pulleys inside the machine and placed under stress. The wire continues at high speed, which is cut through the material.

The vertical design means that the wire goes up and down, which allows the workpiece to be placed on a flat table and cut with large stability. Because diamonds are the most difficult known materials, they can easily cut through hard ingredients such as sapphire, quartz, ceramic and silicone carbide. The process produces very little heat, which prevents damage to sensitive materials. It also produces a very smooth cut surface, reduces the need for additional polishing.

Key Features That Ensure Precision and Efficiency

Vertical diamond wire cutting machines are loaded with features that help achieve the correct results. One of the most important characteristics is a closed-loop wire tension control. This ensures that the wire remains tight and stable during cutting, which helps to avoid breaking of wire and improves accuracy.

Another feature is the speed of the adjustable wire. Different materials require different speeds to get the best cuts. The vertical stone and ceramic cutting machine allows operators to control speed easily. Some machines also include automatic wire winding systems, which change the wire simply and quickly or rewind again.

High-quality vertical diamond wire cutting machines also come with accurate work. These tables are often motorised, which allows for the smooth movement of the workpiece. This results in a straight, even cut each time. Additionally, machines often include a cooling system that uses water or other fluids to keep the wire cool and cut the debris.

Advantages of Using a Vertical Diamond Wire Cutter

There are many reasons that manufacturers select vertical diamond wire cutting machines. One of the biggest benefits is high precision. Because the diamond wire is extremely thin, it can produce very narrow cuts, which means less material is wasted. It is very important when working with expensive materials like sapphire or silicon.

Another major benefit is smooth cutting with minimal damage. Traditional saws may contain a war of microcracks, peels or brittle materials. Diamond wire cutting is avoided by these problems. It is also a clean process, as most machines use water or coolant to remove dust and particles during cutting.

High-efficiency diamond wire saw equipment are also energy-skilled. The process requires less power than other cutting methods, which helps to protect operational costs. Finally, these machines are versatile and can be used for many materials, making them an excellent investment for manufacturers.

Applications Across Different Industries

In many industries, vertical diamond wire cutting machines are used. In the optical industry, they are used to cut glass lenses, prisms and other components with extreme accuracy. In the electronics industry, they are used to slices of wafers made of silicon, sapphire, or gallium arsenide for use in semiconductors and LEDs.

The aerospace industry uses these machines to cut overall materials and ceramics for high-demonstration parts. The research and scientific community also depends on the vertical diamond wire cutting machines to prepare samples for studies. Even the medical industry uses them to cut special materials for medical equipment.

Because vertical wafer slicing machine provide such clean and accurate cuts, they are perfect for industries that cannot bear mistakes. Their ability to handle very hard, brittle materials makes him a favourite option for modern, high-technical production lines.

Different Parts of this Wire Cutting Machine

A vertical diamond wire cutting machine is made up of several important parts. Diamond wire is the heart of the machine. It is coated with fine diamond particles and is designed for several cuts before replacement is required.

Puli and wire guides are responsible for moving the wire in a smooth and controlled manner. These parts must be carefully aligned to avoid vibrations and ensure straight cuts. Workable is where the material sits while cutting. It is usually motorised for flat, adjustable and sometimes for accurate movement.

The drive motor gives power to the wire movement, while the tensioning system keeps the wire tight. The machine also includes an electronic control room that allows operators to accommodate cutting speed, stress and other settings. A coolant system helps to keep the wire and workpiece cool, prevents overheating and ensures a smoothly chopped surface.

Diamond Wire Cutting Machine Materials

High-quality vertical diamond wire cutting machines are finalised. Frames and bodies are usually made of heavy-duty steel or aluminium for strength and stability. Puli and wire guides are often made from materials resistant to wear, such as ceramic or rigid steel, to handle frequent use.

To keep the worktable completely flat, it is made of accurate-mashini metal. Diamond wire itself is made from a strong steel core coated with industrial diamonds, which are bound by using advanced techniques to ensure durability.

Electrical components are chosen for reliability and accuracy, while the coolant system is made from corrosion-resistant materials to handle water or other cooling fluid without damage.

Choosing the Right Vertical Diamond Wire Cutting Machine

Choosing the right machine for your requirements depends on some factors.

- Think of the materials you must be biting. Some machines are designed for very difficult materials such as sapphire and silicon carbide, while others are better for glass or ceramic.

- You should also look at the cutting capacity of the machine. Ensure that it can handle the size and thickness of the workpiece you are using. Check the wire speed range, tension control system, and whether the machine has automatic features that save time.

- It is also important to choose a machine from a reliable manufacturer that provides after-sales service, spare parts and technical support.

Reliable Supplier for a Powerful Wire Cutting Machine

If you are looking for a reliable and high-tech supplier, Vimfun is an excellent option. They are a major manufacturer focused on developing and producing advanced diamond wire cutting equipment. They specialise in machines for optical glass, sapphire, quartz and other ultra-kiss or brittle materials.

Vimfun’s advanced diamond wire cutting technology are widely used in optics, photonics, infrared imaging, laser systems and scientific research. They are known to provide accuracy, stability and efficiency. By choosing Vimfun, you only get more than a machine – you get expert support, a custom solution and a partner that helps your business to succeed.