As environmental concerns reshape the optical lens manufacturing industry, sustainable technologies are becoming a priority for optical shops and labs. The VIMFUN Optical Lens Cutting Device, featuring a state-of-the-art ring-shaped diamond wire design, leads the way in eco-friendly optical glass cutting. With its dry cutting capability, coolant recycling system, and mist recovery technology, this device minimizes environmental impact while delivering precision cuts for K9 glass, germanium glass, and Schott glass (e.g., BK7). This article explores why the Optical Lens Cutting Device is the top choice for sustainable optical manufacturing, aligning with market trends and addressing customer demands for green solutions.

The Growing Demand for Sustainable Optical Cutting

The optical lens cutter market is projected to reach USD 973.2 million by 2032, driven by a 9.2% CAGR and a shift toward eco-friendly technologies. Traditional cutting methods, like blade-based edgers or water-intensive laser systems, consume up to 1 million liters of water annually and generate significant waste. X discussions in r/Optics and r/CNC highlight a rising interest in sustainable alternatives that reduce water usage and environmental footprint. The VIMFUN Optical Lens Cutting Device addresses these concerns with innovative features, making it ideal for environmentally conscious manufacturers cutting high-value optical materials.

Eco-Friendly Features of the VIMFUN Optical Lens Cutting Device

The Optical Lens Cutting Device integrates several sustainable features that set it apart from traditional blade and laser cutters:

- Dry Cutting Capability: Unlike water-reliant systems, the VIMFUN device supports dry cutting, eliminating water consumption entirely. This feature, noted in industry reports as a game-changer, saves resources and reduces wastewater management costs, appealing to labs prioritizing sustainability.

- Coolant Recycling System: For clients preferring oil-based coolants, the device includes a recycling system that minimizes coolant waste, ensuring eco-friendly operation even in wet cutting scenarios.

- Mist Recovery Technology: The built-in mist recovery system captures and filters cutting byproducts, protecting air quality and reducing environmental pollution, a key concern in modern manufacturing.

- Energy Efficiency: With automated features like auto-slicing, complex shape cutting, and tilt functions, the device optimizes energy use, streamlining production for lenses ranging from 1 mm to 3 meters in diameter and 0.1 mm to 1 m in thickness.

These features align with the industry’s push for green technologies, as seen in discussions about waterless cutting systems saving millions of liters annually.

Precision and Versatility Without Compromise

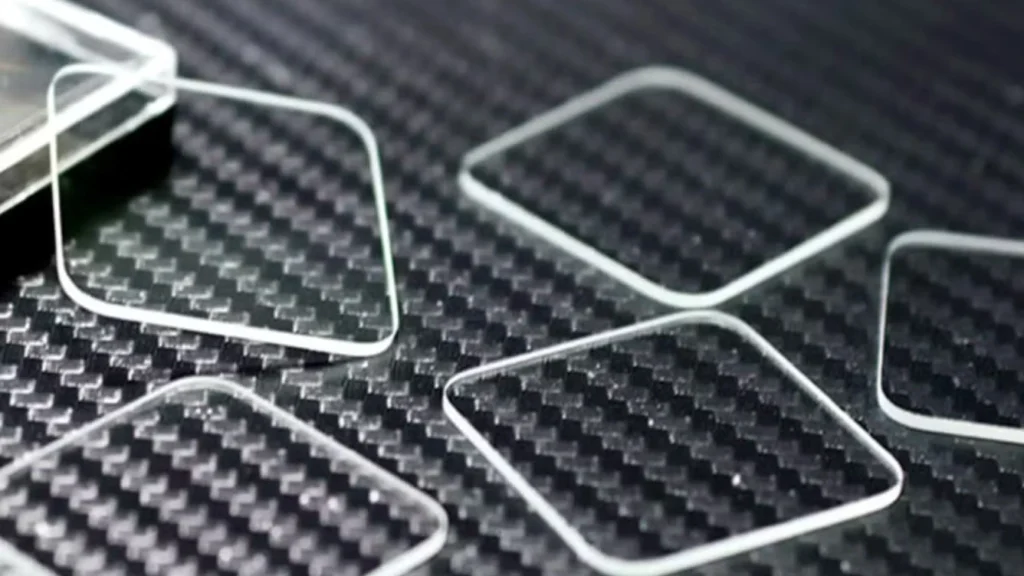

Sustainability doesn’t come at the cost of performance with the Optical Lens Cutting Device. Its ring-shaped diamond wire, operating at speeds up to 80 m/s, achieves a cutting tolerance of 0.03 mm, ensuring micron-level precision for K9, germanium, and Schott glass. The unidirectional wire motion delivers smooth, chip-free surfaces, ideal for high-clarity lenses and infrared optics. The device’s versatility—handling micro-lenses to large 3-meter components—makes it suitable for both small optical shops and large manufacturing labs, addressing X user needs for material compatibility and precision.

Glue Selection for Eco-Friendly Cutting

To maintain optical quality, the Optical Lens Cutting Device pairs with UV-curable glues like Norland NOA68, selected based on material characteristics (e.g., germanium’s sensitivity). These glues:

- Minimize Solvent Use: Peel cleanly with heat (80-100°C) or hot water/isopropyl alcohol, reducing chemical waste compared to traditional optical wax.

- Ensure Stability: Provide strong bonding during high-speed cutting, preventing lens displacement.

- Protect Surfaces: Avoid residue on delicate germanium coatings, a concern raised in r/CNC discussions.

This glue compatibility enhances the device’s eco-friendly profile by reducing post-cutting cleaning needs, aligning with sustainable manufacturing goals.

Why Choose the VIMFUN Optical Lens Cutting Device?

The VIMFUN www.endlesswiresaw.comOptical Lens Cutting Device stands out for its:

- Eco-Friendly Design: Dry cutting, coolant recycling, and mist recovery minimize environmental impact.

- High Precision: 0.03 mm tolerance for flawless K9, germanium, and Schott glass cuts.

- Versatility: Supports lenses from 1 mm to 3 meters, suitable for diverse applications.

- Cost Efficiency: Reduces waste and operational costs for small shops and large labs.

- Automation: Streamlines production with auto-slicing and complex shape cutting.

Conclusion

The VIMFUN Optical Lens Cutting Device is the ultimate choice for eco-friendly optical glass cutting, combining sustainability with precision and versatility. By eliminating water usage, recycling coolants, and ensuring clean cuts for K9, germanium, and Schott glass, it meets the demands of modern optical manufacturing. Whether you’re a small shop or a large lab, this device delivers green, high-quality results. Visit www.opticalcutting.com to learn how the VIMFUN Optical Lens Cutting Device can transform your sustainable optical production.