In today’s factories, cutting hard materials is not easy. Quartz, sapphire, and other crystals are strong and brittle. They can crack or break if cut the wrong way. Many industries need tools that are fast, safe, and precise. Electronics, aerospace, and gemstone makers all rely on careful cutting. Quartz Cutting Wire is one tool that helps them work smoothly. It is built to handle hard materials. It slices them cleanly. It keeps edges smooth and waste to a minimum. Its innovative design enables machines to run continuously without stopping.

Cutting quartz is tricky. Regular saws often cause cracks or chips. They waste a lot of material. This Cutting Wire solves this problem. It is designed to cut hard crystals with precision. The wire is thin but strong. It leaves minimal kerf, which means it wastes almost no material. Its coating makes it last longer. Even in large factories that operate 24/7, this wire performs well. It is consistent, safe, and efficient.

The Role of Electroplated Diamond Wire in Modern Cutting

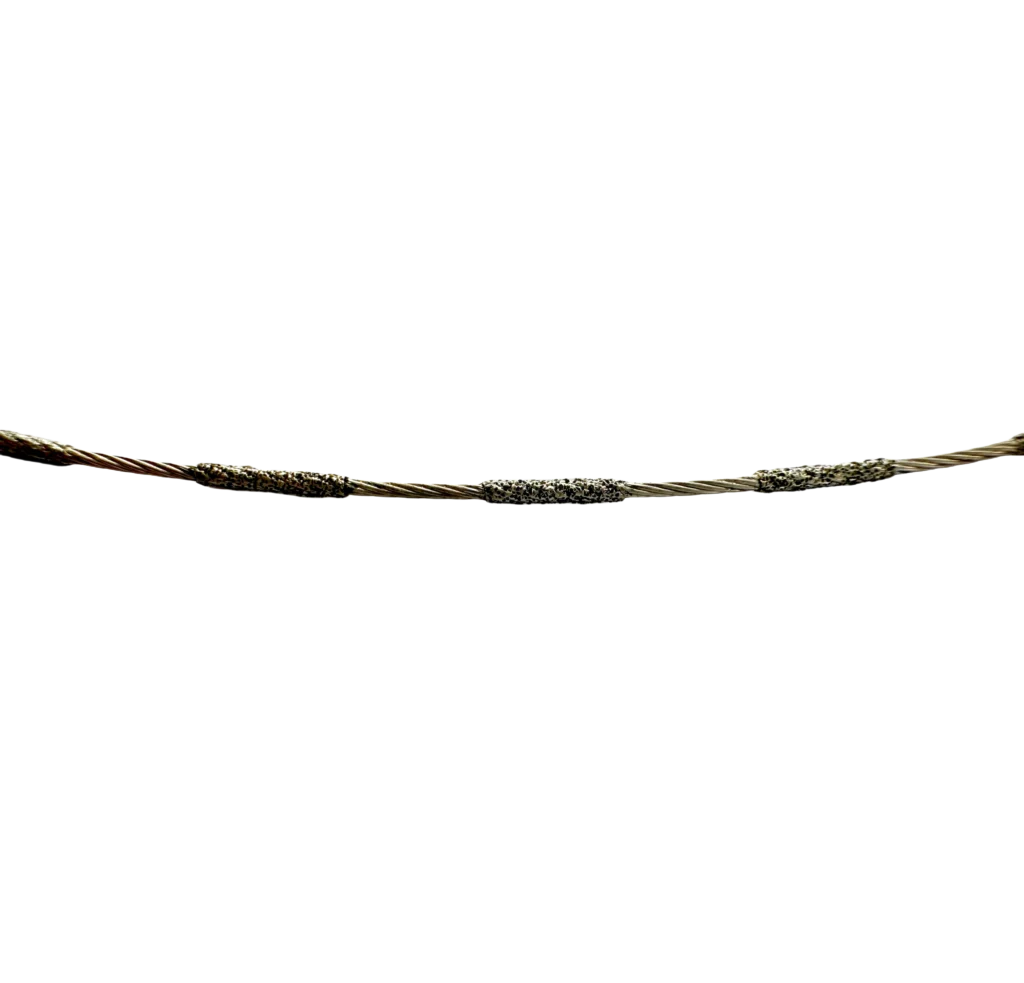

Many factories use electroplated diamond wire to cut hard materials. Tiny diamond particles are stuck to a metal wire. Quartz Cutting Wire makes the wire very strong. The diamonds do most of the cutting. The wire lasts long and cuts cleanly. Each diamond is placed carefully. This keeps the wire efficient. It wears down slowly.

A diamond electroplated wire saw is a tool that uses this wire. It cuts quartz, sapphire, and semiconductor wafers. These saws remain precise, even when running for extended periods. They handle brittle materials without cracks or chips. They are also flexible. They can cut a wide range of shapes and sizes. For factories that require precise results, this wire is ideal.

Diamond Wire Loops and Precision Operations

Diamond wire loop technology is a big help for precise cutting. A loop is a continuous wire with diamonds on it. It moves in a circle. The tension stays even. The cutting speed is steady. This makes smooth edges and low waste.

Diamond cutting wire loop tools are used to cut quartz, sapphire, and wafers. They are great for delicate materials. They prevent damage and keep pieces intact. The loop design also reduces downtime. Machines can run longer without stopping. Factories can produce more, faster.

Available Specialized Full-Coated Quartz Cutting Wire

- The Full-Coated Quartz Cutting Wire is very reliable. Unlike wires with gaps or segments, this wire has diamonds along its whole length. The cutting is even from start to finish. The wire lasts longer and cuts more smoothly.

- This wire is best suited for use with brittle materials. Quartz, sapphire, and semiconductor wafers are easy to cut with it. It leaves minimal kerf, which saves material. It keeps measurements precise. Factories that use this wire need less maintenance. They can cut faster and reduce interruptions.

- It fits many machines, like diamond saws or dicing tools. The wire is strong enough for continuous work. Its full coating protects it and makes it last longer. Factories replace the wireless equipment more often. Production runs without problems.

Segmented-Coated Diamond Wire for Targeted Applications

Some wires have diamonds in sections. This is called Segmented-Coated Diamond Wire. The segments are spaced along the wire. This helps cut thick or rigid materials. It maintains depth and speed control.

Segmented wires are often used for quartz and sapphire. They remove heat and chips during the cutting process. This stops cracks in brittle materials. Factories that slice high-quality pieces usually choose this wire. It protects expensive materials. The results are precise and consistent every time.

Thread-Coated Diamond Wire for Fragile Materials

Thread-Coated Diamond Wire is used for very delicate materials. Fine diamond threads wrap around the wire. This spreads pressure evenly. It also makes cutting smoother and safer.

This wire is excellent for brittle material cutting. Quartz, sapphire, and ceramic pieces are safe with it. It reduces vibrations and stops chipping. It also works well for semiconductor wafers. The surface stays smooth. Factories that need perfect edges rely on this wire.

Minimal Kerf Cutting Wire for Maximum Efficiency

Minimal Kerf Cutting Wire cuts skinny slices. It wastes almost no material. Thin pieces stay safe and strong. Cutting is precise, clean, and fast.

It is used for quartz, sapphire, and semiconductor wafers. Minimal kerf saves money. It keeps delicate wafers intact. When combined with diamond technology, this wire strikes a balance between precision, durability, and efficiency. Factories can cut more pieces with fewer losses.

Specialized Cutting Applications

Quartz cutting wires are used in many industries. Sapphire cutting wire is used in the manufacture of LED screens and lenses. Semiconductor dicing wire cuts wafers into tiny chips.

Each type of wire has a special job. Full-coated wires give smooth cuts. Segmented or thread-coated wires help protect delicate materials. Factories can choose the correct wire for each job. The result is precise, clean, and of high quality.

Advantages of Industrial-Grade Quartz Cutting Wire

These wires make factory work easier. They last long and reduce downtime. Machines can cut more pieces without stopping. The cuts are clean, and materials are not wasted. Quartz Cutting Wire fits most machines. It works in big production lines and delicate operations. Factories can produce more parts at a lower cost. They consistently receive strong, smooth pieces.

Boost Precision Cutting with Quartz Cutting Wire

Take your cutting work to the next level with Quartz Cutting Wire from Vimfun. Our wires cut quartz, sapphire, semiconductor wafers, and other hard or brittle materials with ease. They consistently make smooth and clean cuts. No cracks. No chips. No waste. Vimfun offers a variety of wire types, including full-coated, segmented, and thread-coated.

You can pick the correct wire for your job. Each wire is strong and lasts a long time. It works well in busy factories and under heavy use. Using Vimfun’s Cutting Wire saves time and helps you work faster. You consistently achieve outstanding results. Don’t settle for less when precision is needed. Visit Vimfun today. Find the best Cutting Wire for your factory. Cut smart, safe, and clean with Vimfun.

Quartz Cutting Wire helps cut quartz, sapphire, and wafers safely. Full-coated, segmented, and thread-coated wires are suitable for a wide range of applications. These wires save time, reduce waste, and make work easier.

FAQs

- What is this Cutting Wire?

This cutting Wire is a strong wire with a diamond coating. It cuts quartz, sapphire, and wafers smoothly and safely.

- Why is Quartz Cutting Wire important?

It enables precise cutting and reduces cracks, chips, and material waste in factories.

- What types of Quartz Cutting Wire are there?

There are full-coated, segmented, thread-coated, and minimal kerf wires for different cutting needs.

- Where is Quartz Cutting Wire used?

It is used in factories for quartz, sapphire, semiconductor wafers, and other hard or brittle materials.

- What are the benefits of using Quartz Cutting Wire?

It saves time, reduces waste, improves efficiency, and keeps materials safe during the cutting process.

- Can Quartz Cutting Wire cut delicate materials?

Yes, it is designed to cut fragile and brittle materials without causing cracks or damage.