Quartz is one of the hardest and most useful materials in the world. It is used in industries like electronics, optics, and semiconductors. Cutting quartz, but, is not easy. Traditional methods often create rough edges, cracks, or waste. In high-tech industries, these problems can lower product quality and increase costs.

To solve this challenge, many industries now rely on the High-Precision Quartz Slicing Machine. This advanced tool provides smooth, clean, and accurate cuts while reducing material loss. It uses modern technology to handle quartz and other brittle materials with care.

Learn what a quartz slicing machine is, explore its key features, highlight its benefits, and look at its applications.

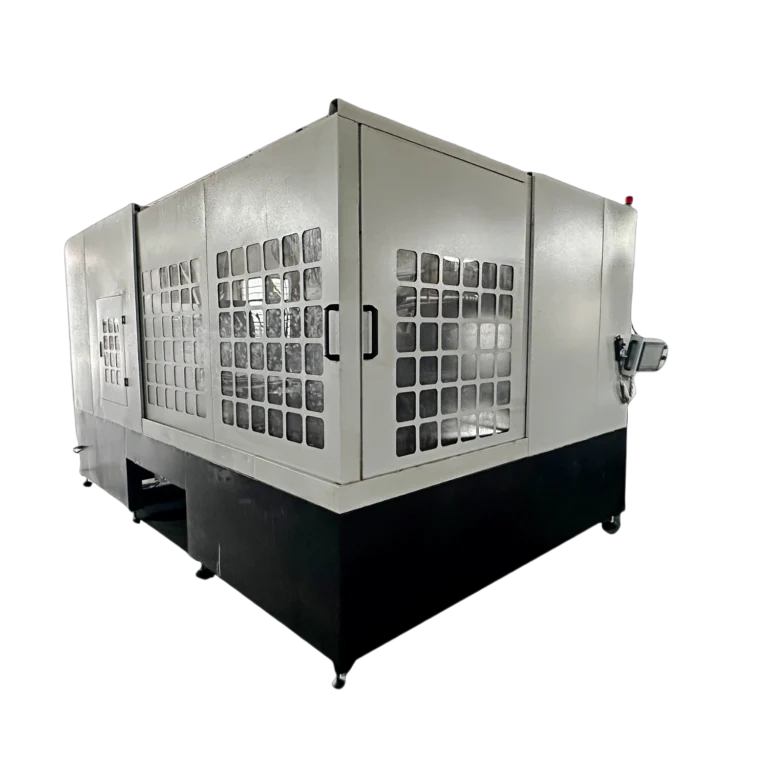

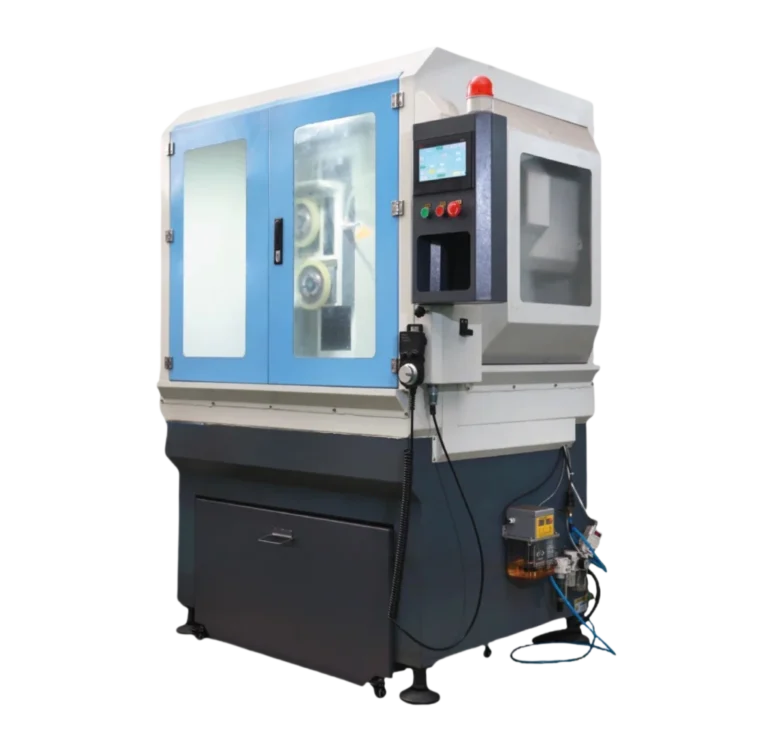

Buy Advanced Quartz Slicing Machine

Die SH60-R Quartz Slicing Machine is designed to cut quartz, ceramics, and other hard materials with precision. It uses endless diamond wire technology, which makes slicing smooth, clean, and free of chips. This is perfect for industries like optical glass, semiconductors, and scientific materials.

Diese high-precision quartz cutting machine has a fully programmable system. You can set the slice thickness and cutting speed, and it will complete the job automatically with high accuracy. The YZ-axis motion system and 360° rotating table keeps the workpiece steady, so every slice is even and consistent.

The touchscreen interface is simple to use, making the machine easy for operators. A water cooling and circulation system keeps the material cool and protects it from damage. The automatic lubrication system reduces wear on key parts and extends the machine’s life. An oil mist recovery unit ensures the workspace stays clean and safe during operation.

The SH60-R is strong, reliable, and user-friendly. It combines modern technology with smooth operation. If your industry desires high-precision quartz reduction, this gadget offers steady, accurate, and efficient outcomes each time.

What is a Quartz Slicing Machine?

A quartz reducing device is a unique tool designed to cut quartz into skinny slices or specific shapes. Unlike easy saws or blades, this machine uses advanced diamond wire generation. The wire is lined with diamond particles, which makes it extraordinarily strong. Since diamond is the hardest natural material, it can cut quartz with a smooth effect.

Die diamond wire quartz saw is constructed for precision. It permits industries to cut huge blocks of quartz into slices without cracks or hard edges. The reducing method could be very controlled, because of this, the quartz remains solid and is not destroyed.

Quartz slicing machines are used in lots of industries where accuracy is important. From optical lenses to semiconductors, smooth slicing ensures that the final product works as it should. Without such a system, it’d be almost impossible to cut quartz at a commercial scale with high precision.

Key Features of a Quartz Slicing Machine

Die quartz slicing machine comes with advanced features that make it reliable for industries. One of the most important features is the use of endless diamond wire cutting. The diamond wire runs in a continuous loop, which makes the cutting process smooth and stable. Because the wire is very thin, it creates narrow cuts that waste less material.

Another key feature is the horizontal cutting design. This setup keeps the quartz stable while slicing, which reduces vibration and prevents damage. It also makes it easier to cut long or heavy quartz blocks safely.

The machine also includes automatic tension control. This ensures the diamond wire stays tight during cutting, which improves accuracy. Along with this, speed adjustment systems allow operators to control the cutting process for different materials.

Many quartz cutting machines also have oil mist recuperation systems and water recycling structures. These features maintain the place of work clean and protect the surroundings. The closed-loop layout reduces dirt, collects oil mist, and reuses water; that’s secure and efficient.

The system is designed for sturdiness. The chip-free quartz wire saw lasts longer than normal, reducing blades, and the gadget’s sturdy structure allows it to run for years with strong performance.

Benefits of Using a Quartz Slicing Machine

There are many blessings of the usage of an automated quartz cutting system. The first and maximum critical is accuracy. The cuts are easy, even, and free of cracks. This reduces the need for sprucing or extra finishing, which saves money and time.

Another huge benefit is low kerf loss. The kerf is the amount of material lost during reducing. Because the diamond wire is so thin, the machine produces kerf widths as slender as 0.8mm. This way little or no quartz is wasted, which is a huge benefit while running with luxurious substances.

The device also facilitates performance. It can cope with both big blocks and thin slices, making it flexible for many uses. At the same time, its solid layout and coffee cutting force prevent chipping or microfractures, which maintains the material’s safety.

Another gain is protection. The device reduces vibration and consists of protective structures like enclosed designs and oil mist recovery. This creates a more secure working environment for operators.

The device is value-powerful. While it can look like a massive investment, its durability, accuracy, and material savings make it a smart choice for any commercial industry working with quartz or other difficult substances.

Applications in Optical Glass, Semiconductors, Industrial Materials

The quartz reducing device is extensively used throughout industries in which precision is needed.

In the optical industry, quartz and optical glass are used to make lenses, sensors, and medical devices. These elements need to be cut flawlessly to keep away from flaws that would affect performance. The quartz slicing machine ensures easy and chip-free cuts that meet high standards.

In the semiconductor industry, quartz and silicon wafers are important materials. These wafers form the base of microchips and digital circuits. Since even tiny defects can break a semiconductor, the slicing procedure ought to be extremely unique. The optical glass slicing machine makes this viable.

In commercial materials, quartz and sapphire are used for aerospace, defence, and medical equipment. For instance, quartz plates are utilized in radiation protective glass, and sapphire is utilized in advanced electronics. These substances are very hard but also brittle, so smooth reducing is critical.

Why Choose Our Quartz Slicing Machine for Your Cutting Needs?

Not all machines are equal. Choosing the right quartz-reducing gadget can make a huge difference in your production method. Our machines are designed for the ultra-modern generation to ensure easy, correct, and efficient cuts.

We construct machines with sturdy systems, solid designs, and superior management structures. With infinite diamond wire reducing, automatic tension manipulation, and efficient systems, our machines are geared up to satisfy modern business needs.

Unser Industrial quartz cutters are also dependable and constructed to last. They lessen waste, shop fees, and enhance safety. Whether you are cutting quartz cylinders, optical glass, or semiconductor wafers, our machines offer a strong performance that you can consider.

We also understand that different industries have unique wishes. That is why we offer custom-designed solutions for quartz, sapphire, optical glass, and other brittle substances. This guarantees that you get the best results for your particular reduction tasks.

Reliable manufacturer for Quartz Slicing Machines

When it comes to buying a quartz block slicing equipment, first-class quality and reliability are very crucial. Cheap machines may also store cash at the beginning, but they often create problems like terrible cuts, common breakdowns, and wasted substances. This can harm your industry ultimately.

One trusted name in this field is Vimfun. They are a high-tech manufacturer that focuses on developing and producing advanced diamond wire cutting equipment. Their machines are designed for optical glass, sapphire, quartz, and other ultra-hard or brittle materials.

Vimfun invests heavily in research and development. This means their machines are always updated with the latest technology and safety features. Industries around the world use their machines because they deliver clean, accurate, and stable results.

By choosing them, you get more than just a machine. You get long-term reliability, strong support, and advanced performance for your business. Whether you are in optics, electronics, or industrial manufacturing, Vimfun offers solutions that meet your needs.