Cutting hard materials like stone, glass, or silicon used to take a lot of time and effort. But now, thanks to field connectable diamond wire, cutting has become fast, easy, and strong. This smart wire helps workers in many industries save time, reduce waste, and get smooth, clean results.

Whether you are in a lab, factory, or construction site, this type of Fil diamanté connectable can be used right where you are. You don’t need special tools to connect it. You can do it in the field, right on-site. That’s why more and more people are choosing this modern cutting solution.

We’ll explore diamond wire with on-site connection, how it works, what types are available, and why it’s such a smart choice. We’ll also look at where it’s used and how to choose the right one.

What Is Field Connectable Diamond Wire and Why Does It Matter

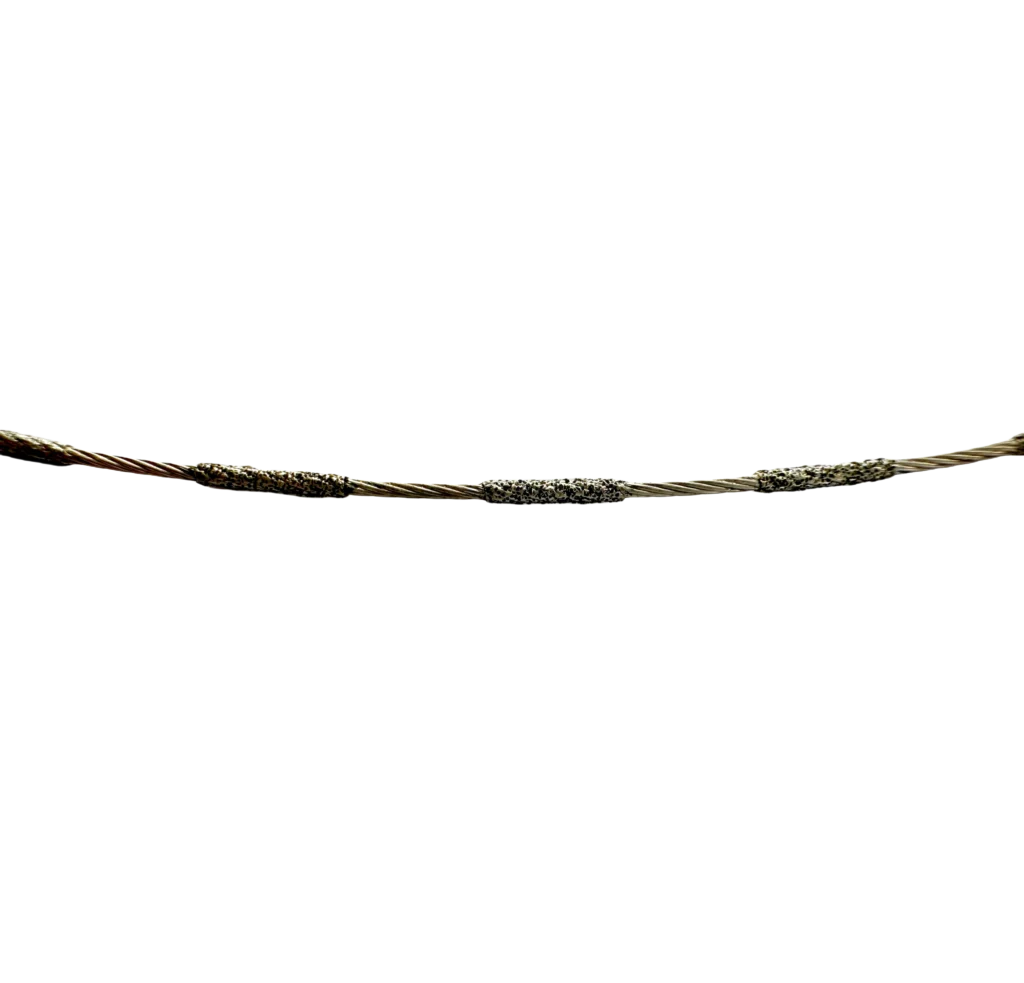

Field connectable diamond wire is a special type of wire used to cut strong materials. The field joint diamond cutting wire is coated with diamond grains. These tiny diamonds are very hard and sharp. When the wire moves, it cuts through tough items like silicon, granite, and glass.

What makes it special is that you can connect it yourself, right where you work. You don’t have to send it back to the factory or use fancy tools. This saves time and makes the job easier.

In places where speed and quality matter, like semiconductor labs or stone workshops, this wire becomes a powerful tool. You just connect it, set it up, and start cutting. That’s why it matters so much. It puts control in your hands, right on the job site.

Types of Diamond Wire Loop

There are a few kinds of easy-Fil diamanté connectable loops depending on how they are made and what they are used for. Understanding the types helps you pick the best one for your needs.

The endless diamond wire loop is shaped like a ring. It keeps spinning around during the cut. This type is often used in machines where the wire moves in a circle again and again. It’s perfect for long, smooth cuts.

The open-ended Connectable Diamond Wire is straight and has two ends. You can connect these ends easily. This is the kind used for field connectable systems. It’s flexible and works great in places where you might need to replace or join wires on the spot.

Then, there’s the coated diamond wire. Some wires are fully coated, while others have only the middle part coated with diamond. Fully coated wires cut longer and are more durable. But partially coated wires are good for soft materials and cost less.

Knowing the type of quick splice diamond wire system helps you choose wisely. Whether you need long-lasting cuts or fast replacements, there’s a type for your task.

How Field Connections Make Diamond Wire Cutting Faster

Field connectable diamond wires make cutting jobs much faster. Why? Because you don’t have to wait. You don’t need to stop your work to send a wire for joining or get a new one from the warehouse. You can just connect the wire yourself, right there in the field.

Let’s say you’re cutting stone on a construction site. If your wire breaks, normally you’d wait hours to fix it. But with a field-connectable wire, you can make a new loop in minutes. That means less waiting, more cutting, and faster jobs.

Connectable Diamond Wires are easy to handle. The ends are made to be joined quickly using simple tools. Some even use snap-fit or crimping systems. No high heat or welding needed. Anyone with basic training can do it.

Instead of stopping work, you keep moving. That’s how field connections save time and boost speed.

Key Benefits of Durable Field-Ready Diamond Wire

Field connectable diamond wires come with many strong benefits. They are easy to set up. You don’t need special tools or a skilled technician. You just follow a few steps, and the wire is ready to cut.

They are durable. These wires are built to last. The diamond coating is tough. It does not wear out fast, even on hard materials. You can use them again and again without losing cutting power.

Another big benefit is that you can use them anywhere. In a clean lab, a busy factory, or out on a dusty building site, this wire works. It doesn’t need special air or tools to connect. That makes it perfect for fieldwork.

It also gives you more freedom and control. You don’t have to rely on outside help. You can keep working even if the wire breaks or gets dull. That saves time and money. And it keeps your team moving forward.

Top Use Cases in Construction, Semiconductors, and Stone Cutting

Field connectable diamond wire is used in many places. Let’s look at the top industries where it shines the most.

In construction, these wires help cut large stone blocks, concrete, and even steel-reinforced walls. Workers like them because they can join wires on-site without waiting. That keeps big projects on schedule.

In the semiconductor industry, clean and sharp cuts are a must. Diamond wire cutting gives that smooth, dust-free finish. It slices silicon wafers with care and precision. When wires break, teams can fix them quickly, without halting lab work.

In stone cutting, like marble and granite, this wire is a game-changer. It doesn’t crack or chip the material. The cuts are clean and perfect. Plus, because wires can be joined in the field, cutters don’t lose time when wires wear out.

Choosing the Portable diamond wire cutting solution

Picking the right field connectable diamond wire is very important. Think about the material you will cut. Hard items like granite or quartz need a wire with a strong diamond coating. Softer things like glass or plastic need finer wires.

Look at the thickness of the wire. Thin wires make fine, smooth cuts. Thicker wires cut faster but may not be as neat. Think about whether you want speed or polish.

You should also think about wire length. Make sure it fits your machine. Some machines need long loops. Others work with short ones. Always check the user guide.

Think about the connection type. Some wires come with special clips or crimps. Others need manual joining. Choose what works best for your setup and skill level.

Always choose wires made by trusted companies. Poor-quality wires break fast and waste time. That’s why many people choose Vimfun.

Experts in Diamond Wire Solutions – Why Choose Vimfun?

Lorsqu'il s'agit de jobsite connectable diamond wire solutions, Vimfun is a name you can count on. They have many years of experience in making cutting tools and machines. Their products are trusted by workers in many fields—from electronics labs to stone yards.

They makes strong, reliable, and easy-to-use field connectable diamond wires. Their wires are tested for strength and safety. They give smooth cuts and last longer than cheap brands.

They also offer full support. If you have questions or need help picking a wire, their team is ready to guide you. They care about your work and want to see you succeed.

They keeps making new tools to match new needs. They work with real users to build better, faster, and smarter wires. That’s why they are leaders in this field.

If you want the best results, go with Vimfun—the experts in diamond wire cutting.