Máquina cortadora de cuarzo

En SH60-R is a high-precision horizontal endless diamond wire saw engineered for slicing quartz blocks, technical ceramics, and other hard, brittle materials. Equipped with a fully programmable YZ-axis motion system and a rotating loading table, SH60-R delivers consistent, chip-free cuts ideal for high-purity optical, semiconductor, and scientific glass applications.

Características principales

Corte de hilo diamantado sin fin

Uses electroplated high-speed diamond wire loop to cut any material softer than diamond — including quartz, optical glass, silicon, and ceramics.Fully Programmable Slicing

Set your desired slice thickness and cutting speed, and the machine will complete the process automatically with ±0.01 mm feed precision.YZ Axis Motion + Rotary Platform

Dual-axis (YZ) linear system driven by servo motors, with a 360° continuously rotating worktable for consistent slicing surface contact.Touchscreen Interface

Equipped with a user-friendly English-language PLC system with touchscreen and hand controller for easy operation.Integrated Water Cooling & Circulation System

Built-in water tank and recirculation system ensure clean, low-temperature operation for sensitive optical materials.Automatic Lubrication System

Key moving parts are automatically lubricated to reduce wear and extend equipment lifespan, requiring minimal manual maintenance.Oil Mist Recovery Unit

Enclosed cutting chamber with built-in oil mist collection system, maintaining a cleaner, safer working environment during high-speed cutting.

SH60-R TECHNICAL SPECIFICATION

| Parámetro | Value |

|---|---|

| Worktable Diameter | Ø600 mm |

| Max Workpiece Height | 500 mm |

| Y-Axis Travel | 315 mm |

| Z-Axis Travel | 500 mm |

| Longitud del hilo de diamante | ~3500 mm |

| Wire Diameter Range | 0.35 – 1.0 mm |

| Max Wire Speed | 84 m/s |

| Min Feed Increment (Y/Z) | 0.01 mm |

| Repeatability (Y/Z) | ±0,01 mm |

| Cutting Speed Range | 0–1000 mm/min (adjustable) |

| Guide Wheel Size | Ø250 mm / Ø180 mm |

| Potencia del motor | 0.75 kW (Max 2800 RPM) |

| Fuente de alimentación | 220V, 50Hz, 3-phase |

| Machine Size (L×W×H) | 1646 × 1733 × 2010 mm |

| Net Weight | ~1300 kg |

| Irregular Shape Cutting | Not supported |

Customer Cutting Videos: Real-World Performance

Comparison Table: Cutting Machines for Large Quartz Blocks

| Método de corte | Precisión | Calidad de la superficie | Ancho de ranura | Velocidad | Suitable Size | Material Loss | Typical Use Case |

|---|---|---|---|---|---|---|---|

| Sierra de hilo diamantado sin fin |     |     | 0.6–0.9 mm | Very–High | Very Large | Bajo | High-precision slicing of quartz, ceramics, glass |

| Multi-Wire Saw |     |   | 0.1–0.3 mm | Medium High | Medium–Large | Bajo | High-throughput wafer slicing (less shape-flexible) |

| Sierra de cinta de diamante |  |  | >1.0 mm | Medio | Very Large | Alta | Rough cutting, pre-segmentation |

| Corte por chorro de agua |   |   | ~1.0–2.0 mm | Medio | Large | Medium–High | Shape-cutting of thick blocks, low thermal impact |

| Corte por láser |  |  | Varies | Alta | Small–Medium | Medium–High | Not ideal for quartz due to poor IR absorption |

| Inner Diameter (ID) Saw |     |     | ~0.3 mm | Bajo | Small (≤300 mm) | Bajo | Thin wafer slicing (small quartz rods/discs) |

HOW IT WORKS: INSIDE THE SH60-R

TYPICAL APPLICATIONS OF THIS GRAPHITE BOAT CUTTING MACHINE

Quartz Block Slicing

For optical substrates, IR windows, and high-purity photonic components.

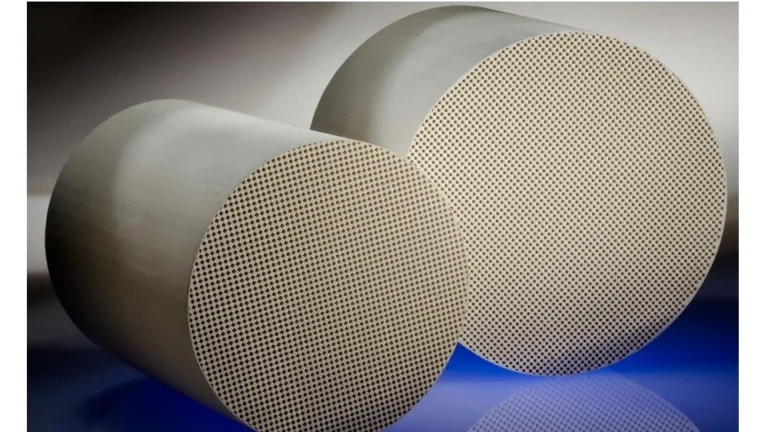

Ceramic Material Processing

Suitable for Al₂O₃, AlN, Si₃N₄, and other engineering ceramics used in electronics and optics.

Optical Glass Plate Cutting

For clean slicing of optical components such as filter substrates or laser windows.

Semiconductor Material Pre-processing

For slicing silicon ingots or related high-value brittle materials.

WHY CHOOSE US

High-Speed Endless Wire Cutting

High-Rigidity Cast Structure

High-Precision Guide Rails and Ball Screw

Automatic Constant-Tension System

Micron-Level Feed Control

User-Friendly Smart Interface

Fully Enclosed Protective Design (Optional)

Low Maintenance & Cost Efficiency

Modular Design

Low Maintenance & Cost Efficiency

Automatic Lubrication System

Testimonios de clientes

Preguntas frecuentes

¿Cuál es el grosor máximo que puede cortar la máquina?

¿Cuál es la diferencia entre esta sierra de hilo y la sierra de cinta?

La velocidad de corte sería similar, pero la calidad de la superficie de corte de la sierra de hilo es mucho mejor y la pérdida de corte es menor.