Cutting hard and fragile materials is not easy. You need a machine that is both strong and gentle. That’s where diamond wire cutting machines come in. These machines use a special wire with tiny diamonds on it. The diamonds help slice through very hard materials like glass, sapphire, and quartz.

If you want smooth and accurate cuts, a Industrial diamond wire saw is a smart choice. These machines are used in many industries today. They help make neat cuts without breaking or cracking the material.

You will learn what a diamond wire cutting machine is, how it works, why it’s useful, and where you can buy one. We’ll also tell you about a trusted brand, Vimfun, that makes some of the best machines on the market.

Top-Quality Diamond Wire Cutting Machines Available

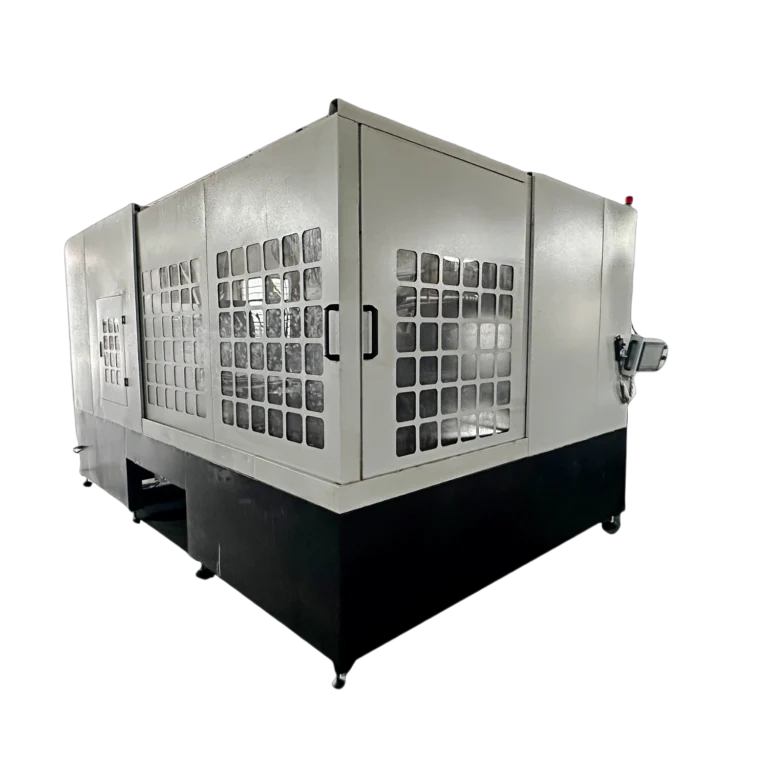

If you are seeking out an effective and particular reducing device, the SGS180-90 Diamond Wire Cutting Machine is a top choice. It is constructed for cutting larger blocks of optical glass, particularly high-purity quartz. This system can cope with substances as much as 1800 mm and 900 mm, making it best for factories and research facilities that work with massive glass portions.

The SGS180-90 uses an endless diamond wire that moves up and down while also shaking side to side. This special movement helps make very smooth cuts. The cuts are so clean that you often don’t need to polish the glass afterwards.

Its strong gantry frame and open-side design let you load heavy blocks easily using a crane or forklift. You can also adjust how it holds the material with clamps, magnets, or vacuum chucks.

What Is a Diamond Wire Cutting Machine?

A cortadora de hilo diamantado is a tool used to cut very hard or delicate materials. It works by pulling a thin wire loop that’s coated with tiny diamond bits. Diamonds are the hardest material in the world. That’s why they can cut through things that other tools can’t.

The wire moves at high speed and rubs against the material. It doesn’t chop like a saw. Instead, it grinds the material slowly and carefully. This makes the cutting smooth and gentle. It also creates less dust and waste.

These equipos de corte de alambre de precisión come in different sizes. Some are small for labs, and others are large for factories. No matter the size, they all use the same basic idea: a fast-moving diamond-coated wire that cuts with great care and precision.

Diamond Wire Technology Ensures Smooth and Clean Cuts

Diamond wire technology is different from regular cutting tools. Instead of blades or saw teeth, it uses a strong wire covered in small diamond grains. These grains are very sharp and very hard. As the wire moves, the diamonds scratch and wear away the material.

The cutting happens little by little. That means less damage to the material. There are no big shocks or jerks like you see with saws. The result is a smooth and clean cut, even on materials that are brittle or thin.

En endless diamond wire machine is very thin. This means it cuts a narrow path, called a “kerf.” A small kerf means less waste. It also means the surface of the cut is cleaner, with no need for much polishing afterwards.

Ventajas del uso de cortadoras de hilo diamantado

Using a diamond wire cutting machine gives many clear benefits.

- You get high precision. This means the cut is exactly where you want it, with no cracks or rough edges. That’s very important when cutting things like glass or sapphire.

- These machines are gentle on materials. The cutting does not put too much pressure on the surface. This helps prevent breaks, chips, or damage.

- Another big plus is less waste. The thin wire cuts with a narrow kerf, so you save more of your material. That’s great when working with expensive or rare items.

- Diamond wire machines work on many sorts of substances. You can cut glass, quartz, ceramics, sapphire, and all with the same machine.

- These high-speed glass cutting machine are also quiet and clean. They don’t make as much noise or dust as saws. And because the diamond wire lasts in the long term, you don’t need to exchange it frequently. That saves each person money and time.

Common Applications Across Industries and Materials

Quartz and sapphire cutting system are used in lots of locations. One common use is inside the optics industry. Here, they reduce parts for cameras, lenses, and telescopes. These parts need to be ideal, and diamond wire gives the easy finish wanted.

They are also utilized in electronics and semiconductors. In those industries, small and sensitive parts are crafted from quartz or silicon. The diamond wire makes cuts without destroying the fabric.

Another large place is sapphire cutting. Sapphire is used for watch covers, smartphone monitors, and LED lights. It’s very difficult, so only a diamond can cut it properly. Diamond wire slicing machines are ideal for this task.

In the solar industry, these machines cut thin wafers for solar panels. The cuts should be genuine and easy to make to ensure the panels work properly.

They are also beneficial in labs and research facilities, in which peoples work with advanced materials that need careful handling.

Features for When Buying a Diamond Wire Cutting Machine

If you need to buy a advanced material slicing machine, you need to realise what to search for.

- One key characteristic is precision manipulation. The system should let you manipulate the rate, pressure, and motion of the wire. In that manner, you could get just the proper cut.

- You should also check the thin kerf cutting solution. This keeps the wire tight and stable during cutting. If the wire gets loose, the cut won’t be clean.

- Another important thing is the cooling system. A good machine should have water or other coolants to keep the wire and material from getting too hot.

- Look for a machine that supports different wire sizes. Some jobs need thin wires, while others need thicker ones. A flexible machine gives you more options.

- Take a look at for protection functions. Things like emergency forestall buttons and covers help guard the user and the fabric.

- Reflect on the scale and form of substances you want to reduce. Make sure the device is huge enough and strong enough to meet your desires.

Buy High-Quality Diamond Wire Cutting Machines

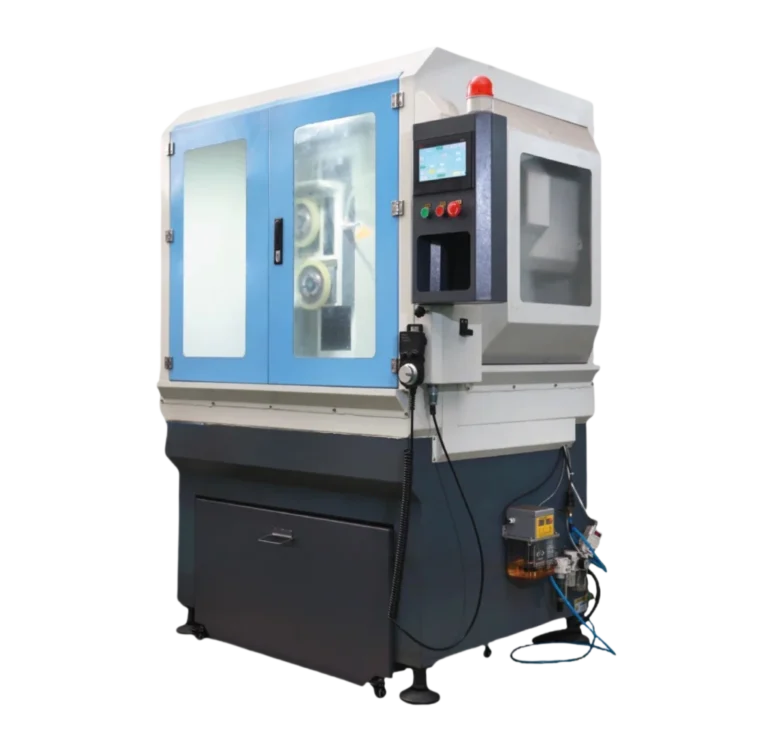

When it comes to shopping for a machine that lasts and works well, you need an emblem you could accept as true with. That’s why many people choose Vimfun.

They are a high-tech producer that focuses on diamond wire cutting solutions. They focus on gear for slicing optical glass, sapphire, quartz, and other ultra-difficult or brittle substances. In that manner, they understand exactly what your slicing process desires.

Vimfun designs its machines for cutting-edge technology. Their machines offer smooth, speedy, and accurate cuts with less waste. They also come with smart capabilities like precise controls, superior cooling, and wire tension systems.

Customers around the world trust them because they make machines that are strong, smart, and safe. Whether you run a factory, a lab, or a workshop, they have a model that fits your needs.

You can also ask them for custom solutions. That means you can get a machine made just for your kind of work. And if you ever need help, their support team is ready to assist.

So, if you want the best cutting results, it’s time to choose Vimfun cortadoras de hilo de diamante.