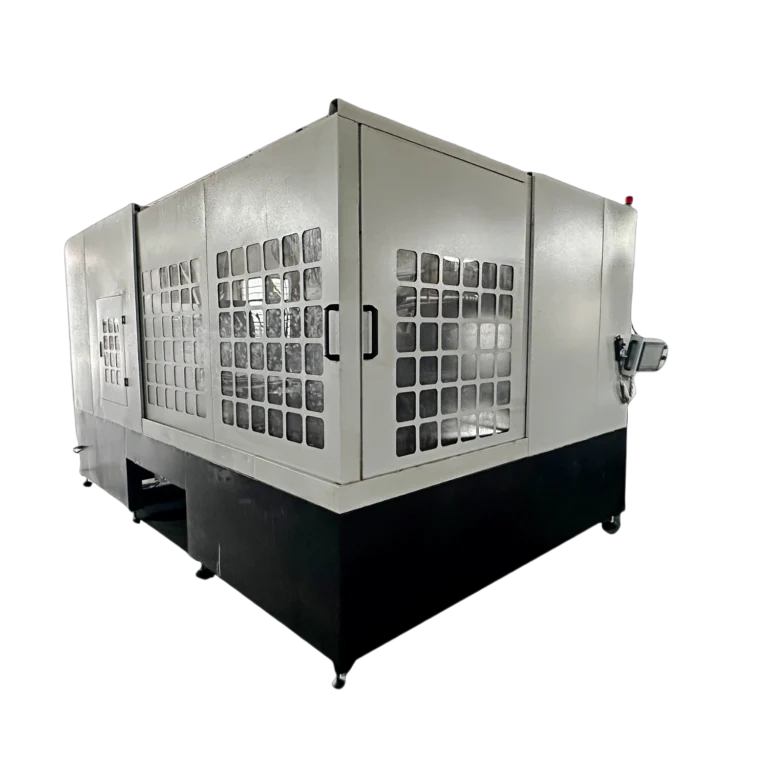

In the competitive world of optical manufacturing, the VIMFUN Optical Glass Cutting Machines stand out with its innovative ring-shaped diamond wire design, redefining precision and efficiency for cutting K9 glass, germanium glass, and Schott glass (e.g., BK7). With a wire speed range of 0-80 m/s, a cutting tolerance of 0.03 mm, and the ability to handle lenses from 1 mm to 3 meters in diameter and 0.1 mm to 1 m in thickness, this machine offers unmatched versatility. This article explores what makes the Optical Glass Cutting Machines unique, highlighting its advanced features, automation, and eco-friendly design that set it apart from traditional blade and laser cutters.

Innovative Ring-Shaped Diamond Wire Design

The VIMFUN Optical Glass Cutting Machines leverages a ring-shaped diamond wire, a significant departure from linear wire or blade systems. This continuous-loop design ensures:

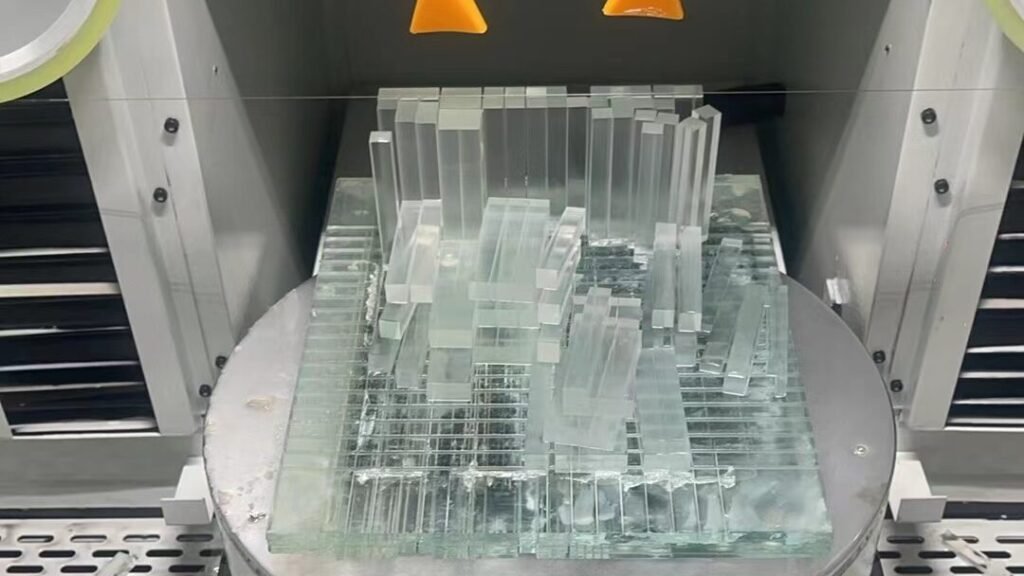

- Consistent Cutting Force: The unidirectional wire motion, operating at speeds up to 80 m/s, delivers smooth, chip-free cuts, critical for high-clarity lenses and infrared optics made from germanium.

- Reduced Vibration: Unlike traditional blade cutters, the ring-shaped wire minimizes vibration, enhancing the 0.03 mm precision and protecting delicate materials like Schott glass.

- Longevity: The wire’s even wear extends its lifespan, reducing maintenance costs compared to blade-based systems like the historical Lemay Electromatic.

This unique design addresses industry demands for precision and efficiency, as seen in the growing optical lens cutter market (9.2% CAGR through 2032).

Advanced Automation for Streamlined Production

The Optical Glass Cutting Machines incorporates automation features that enhance productivity for optical shops and labs:

- Auto-Slicing: Automatically adjusts cutting parameters for consistent results, minimizing operator input for lenses ranging from micro-lenses to 3-meter components.

- Complex Shape Cutting: Enables intricate lens designs, ideal for custom optical components used in scientific or industrial applications.

- Tilt Function: Allows precise angle adjustments, supporting complex geometries without compromising the 0.03 mm tolerance.

These features streamline workflows, making the machine suitable for both small shops and large-scale manufacturers, addressing needs for high-throughput production.

Versatility Across Optical Materials

The VIMFUN Optical Glass Cutting Machines excels at cutting a wide range of materials, including:

- K9 Glass: Achieves smooth surfaces for high-clarity lenses and prisms.

- Germanium Glass: Cuts infrared optics with residue-free precision, protecting sensitive coatings with UV glues like Norland NOA68.

- Schott Glass (e.g., BK7): Delivers chip-free edges for precision optics.

- Additional Materials: Supports quartz, sapphire, and other optical materials, expanding its applications.

Its ability to handle lenses from 1 mm to 3 meters in diameter and 0.1 mm to 1 m in thickness makes it uniquely versatile for diverse optical needs.

Eco-Friendly and Cost-Effective Design

Sustainability is a key differentiator for the Optical Glass Cutting Machines. It features:

- Dry Cutting: Eliminates water usage, saving up to 1 million liters annually compared to traditional systems, aligning with eco-friendly manufacturing trends.

- Coolant Recycling: Supports oil-based coolants with a recycling system, minimizing waste for clients preferring wet cutting.

- Mist Recovery: Captures cutting byproducts, ensuring clean air and reducing environmental impact.

These features, combined with minimal material waste, lower operational costs, making the machine cost-effective for optical shops and labs.

Glue Compatibility for Optimal Performance

The Optical Glass Cutting Machines pairs seamlessly with UV-curable glues like Norland NOA68, tailored to material needs:

- Strong Bonding: Ensures stability during high-speed cutting (up to 80 m/s).

- Clean Peeling: Removes with hot water (below 100°C) or heat (80-100°C), avoiding residue on germanium coatings.

- Efficiency: Fast curing (5-30 seconds) supports automated workflows, enhancing productivity.

This compatibility ensures optical clarity and streamlines production, addressing common concerns about surface quality.

Why the VIMFUN Optical Glass Cutting Machines Stands Out

The VIMFUN Optical Glass Cutting Machines is unique for its:

- Innovative Design: Ring-shaped diamond wire for low-vibration, high-precision cutting.

- Automation: Auto-slicing and complex shape cutting for efficient production.

- Versatility: Handles diverse materials and lens sizes for various applications.

- Sustainability: Dry cutting and coolant recycling for eco-friendly operation.

Conclusion

The VIMFUN Optical Glass Cutting Machines redefines optical manufacturing with its unique ring-shaped diamond wire, automation, and eco-friendly features. Whether cutting K9, germanium, or Schott glass, it delivers precision and efficiency for optical shops and labs. Visit www.opticalcutting.com to discover how the VIMFUN Optical Glass Cutting Machines can transform your optical production process.