In the world of glass manufacturing, every cut matters. A single mistake can lead to wasted materials, uneven edges, and extra work. That’s why professionals need tools that can deliver perfect results from the very first cut. One of the most advanced tools for this job is the high-accuracy oscillating wire glass slicer.

This precision glass slicing machine is not just about cutting glass. It’s about cutting with precision, speed, and care. Whether it’s for optical glass, sapphire, or quartz, the right slicer ensures the surface stays smooth and clean without chipping. Today, we will explore what this machine is, how it works, and why it’s becoming a top choice for industries.

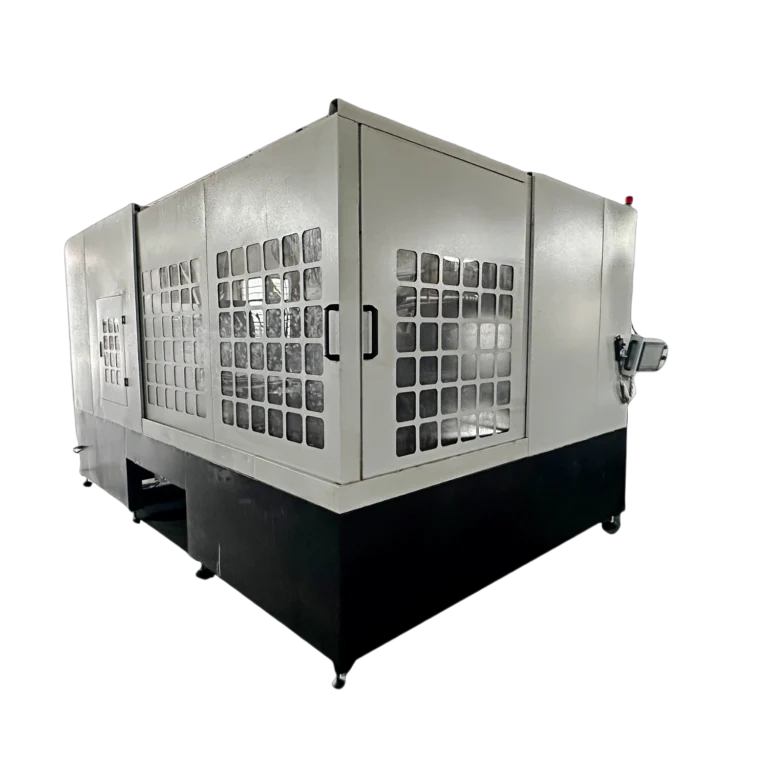

Professional Oscillating Wire Glass Slicer – SGSM 40

The SGSM 40 Oscillating Wire Glass Slicer is constructed for high-precision reduction of medium to massive tough and brittle materials. It handles sapphire, alumina, quartz, ceramics, and extra materials without difficulty. Its vertical, limitless diamond wire design promises clean, smooth cuts without damaging the floor.

One of its best capabilities is the programmable swing-wire motion. The wire actions up and down, even as it reduces, giving a sprucing effect. This creates smoother surfaces, reduces side chipping, and saves time in put processing.

The SGSM forty can work on substances up to 400 × 400 × 400 mm, making it best for large blocks. Its robust vertical gantry shape ensures accuracy, at the same time as the fully enclosed design keeps dirt contained and operators secure.

With its touchscreen and handheld far flung, you may effortlessly set swing diploma, wire velocity, and feed pace. The high-velocity diamond wire machine, driven by a 2100 RPM motor, reaches speeds of 38 m/s for faster reduction.

What Is an Oscillating Wire Glass Slicer?

An oscillating wire glass slicer is a special kind of slicing system designed for very difficult and delicate substances like optical glass, sapphire, and quartz. Instead of the use of a conventional blade, it makes use of a smooth-cut oscillating wire slicer that moves from side to side in tiny, short motions — this is known as oscillation.

This oscillating motion reduces friction, prevents overheating, and permits the wire to make a clean route through the glass. The diamond coating on the wire offers it the energy to cut ultra-tough surfaces without inflicting cracks or difficult edges.

Unlike regular cutters, which often chip or break the glass, an oscillating wire cutting equipment makes every reduce easy and precise. It’s the move-to tool for industries wherein accuracy isn’t a choice — it’s a need to.

Key Features That Deliver Precision and Quality

What makes the high-accuracy oscillating wire glass slicer so unique is an aggregate of clever design and advanced technology. The wire anxiety is cautiously managed to preserve the reduced straight and consistent. The oscillating movement guarantees the wire doesn’t stay in one location too long, which prevents overheating and reduces put on.

Many Industrial glass wire saws also include PC-controlled systems that permit operators to set the reducing pace, pressure, and wire movement. This way, you can regulate it for different glass thicknesses and hardness degrees.

Another key characteristic is its ability to provide micron-degree accuracy. For instance, if a producer needs a pitcher wafer only a few millimetres thick, the slicer can acquire that without breaking the piece. This is mainly crucial for making optical lenses, smartphone screens, and precision devices.

How Oscillating Wire Technology Ensures Smooth Cuts

The magic of oscillating wire reducing lies in how the wire moves. Instead of rotating like a noticed blade, the wire slides back and forth at high pace, even as also slowly moving downward into the glass. This dual motion reduces stress on the material, which prevents cracks.

The diamond coating on the wire acts like tiny slicing factors that shave away at the glass surface, grade by grade. Because the movement is so fine and controlled, the glass doesn’t experience the surprise or vibration that regularly causes damage in conventional cutting.

Water or coolant is also used at some stage in the procedure to scrub away glass dirt and hold the wire cool. This makes the reduction even smoother and keeps the working region easy. The result is a slice so specific that it desires little to no polishing afterwards.

Benefits for Glass Manufacturers and Industries

For glass manufacturers, the advantages of using a high-accuracy oscillating wire glass slicer are clear — and they go beyond just getting a clean cut.

- There’s material savings. Every piece of glass costs cash, and wasted material results in wasted income. With particular reducing, manufacturers can use more of the original glass block without throwing away chipped or broken elements.

- There’s time savings. Smooth, correct cuts imply less grinding and sharpening after reducing. This hastens manufacturing and decreases labour costs.

- It improves the product’s nice. Customers in industries like electronics, optics, and clinical devices call for wonderful products. The oscillating wire slicer promises surfaces so smooth and accurate that they meet the best industry requirements.

- It’s versatile. This high-accuracy optical glass cutter can handle an extensive variety of materials — from fragile optical glass to ultra-hard sapphire and quartz. That flexibility makes it a treasured funding for many manufacturing businesses.

Choosing the Best Oscillating Wire Glass Slicer

Selecting the proper ultra-hard material slicing system relies upon your desires. Reflect on the materials you may reduce most often. Some machines are designed particularly for terribly skinny or delicate glass, even as others are built to address thick and difficult substances.

Recall the system’s accuracy. If your industry requires cuts inside a fragment of a millimetre, look for a model with high-precision controls and solid wire tension.

Take note of the device’s durability. Cutting hard substances like quartz and sapphire can place stress on the wire and body. A true slicer has to have a strong construct and be made from superb components.

One more component to check is the supply of alternative components and guides. A dependable manufacturer will provide clean access to wires, publications, and other additives, together with technical assist while needed.

Where to Buy Reliable Oscillating Wire Glass Slicers?

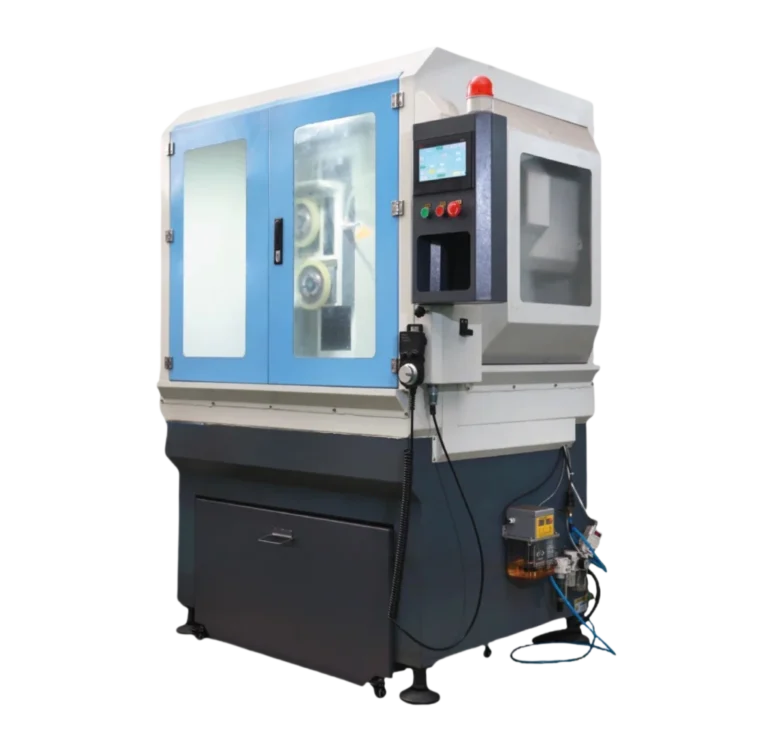

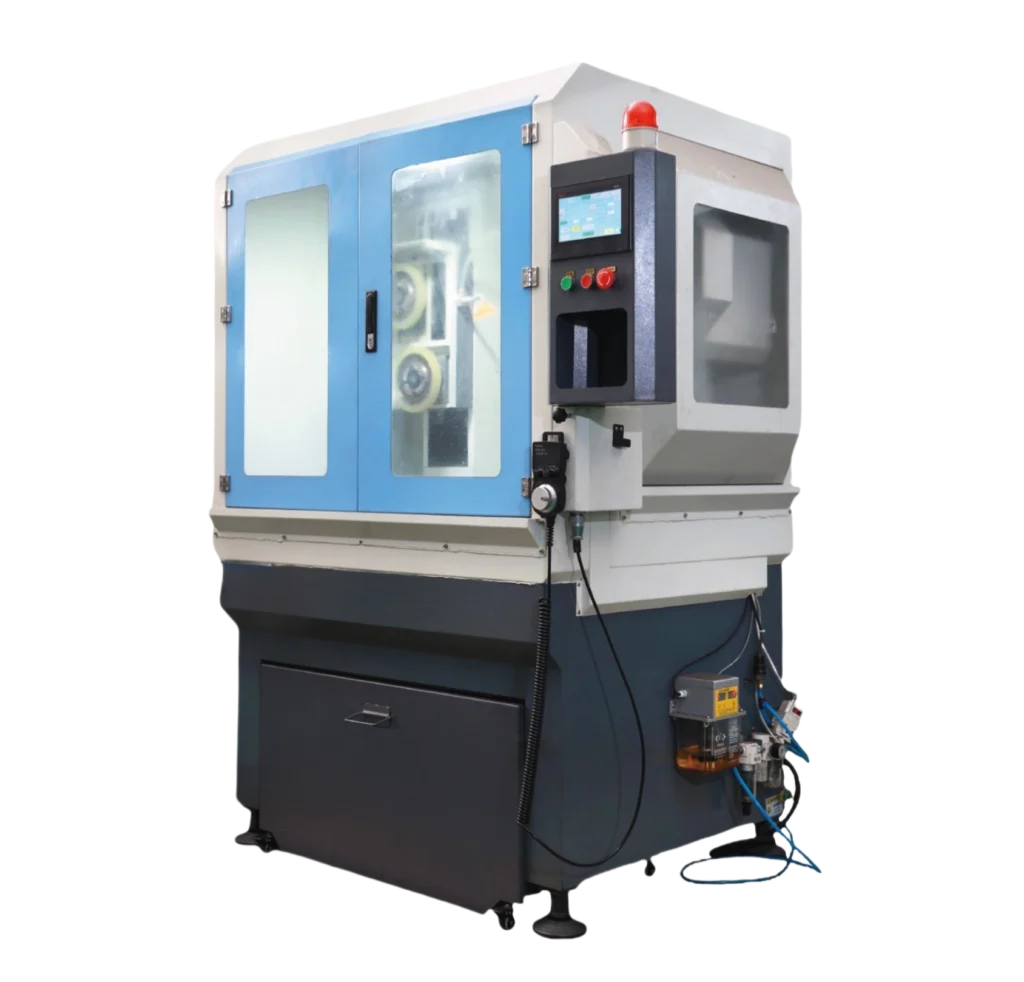

When investing in a high-accuracy oscillating wire glass slicer, you want a dependable supply. This is where Vimfun stands proud. They are a high-tech manufacturer specialising in low-damage glass cutting technology for optical glass, sapphire, quartz, and other ultra-difficult substances.

They design their machines to supply top-degree accuracy while preserving the method clean and green. Their era is widely used in industries that require perfection, from electronics to precision optics.

They also specialise in durability and user-friendly design. This method their machines are constructed to be simple and easy to perform, even for complex projects. With strong after-sales assistance and access to great components, they guarantee that your investment remains productive for years.

If you want to cut glass with confidence, getting a slicer from a trusted name like Vimfun could make a real distinction.