SH200-R

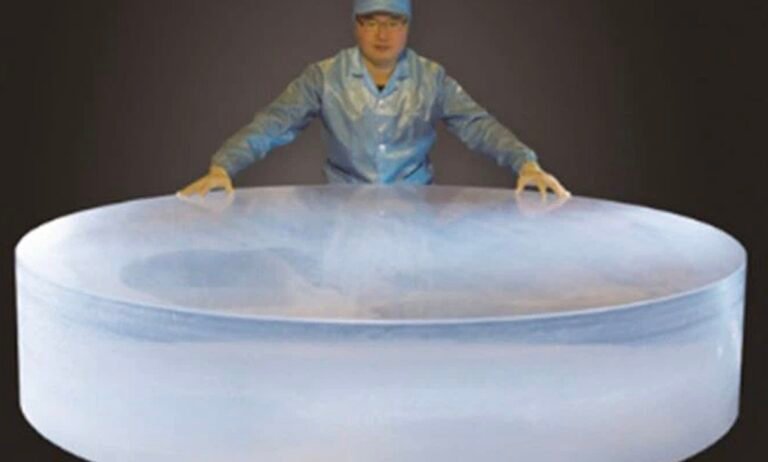

Các SH200-R is a horizontal endless diamond wire cutting machine purpose-built for slicing oversized brittle materials such as quartz, radiation shielding glass, and aerospace-grade optical components. With a wire length of 8.3 meters and support for workpieces up to 2000 mm in diameter, this machine delivers exceptional surface quality and stable performance across industrial-scale cutting tasks.

Key Features of this large-quartz-cutting-machine

Purpose-Built for Ultra Large Workpiece

Engineered specifically for Workpieces up to Ø2000 × 500 mm, such as large quartz cylinders and optical glass plates.Cắt dây kim cương vô tận

Utilizes a high-speed endless diamond wire system for stable, smooth, and chip-free cutting of fragile graphite materials.- Horizontal Cutting Structure

Maximizes stability and accessibility for long or heavy materials, reducing vibration and material deformation. - Low Kerf Loss, High Precision

Achieves clean slicing with kerf widths as narrow as 0.8 mm, minimizing material waste and reducing edge damage. Easy Loading of Elongated Workpieces

Side-loading platform allows easy placement and alignment of large parts using cranes or rollers.- Ultra-Low Cutting Force

Abrasive cutting method reduces mechanical stress on delicate edges, preventing chipping or microfractures - Integrated Oil Mist Recovery System

Fully enclosed design with built-in oil mist collection for a cleaner, safer working environment—ideal for glass and optical material processing. Automatic Lubrication + Water Recycling

Built-in lubrication ensures durability; closed-loop water system minimizes environmental impact.

SH200-R TECHNICAL SPECIFICATION

| No. | Tên | Specification |

| 1 | Maximum Workpiece Dia (mm) | 2000 |

| 2 | Maximum Workpiece Dia (mm) | 2000 |

| 3 | Chiều cao phôi tối đa (mm) | 500 |

| 4 | Worktable X-Axis Travel (mm) | 1015 |

| 5 | Hành trình trục Y của bàn làm việc (mm) | 550 |

| 6 | Tốc độ dây kim cương tối đa (m/s) | 51 |

| 7 | Minimum Feed Increment X-Axis (mm) | 0.01 |

| 8 | Gia tăng nguồn cấp dữ liệu tối thiểu Trục Y (mm) | 0.01 |

| 9 | Repeat Positioning Accuracy X-Axis (mm) | 0.01 |

| 10 | Độ chính xác định vị lặp lại Trục Y (mm) | 0.01 |

| 11 | Tổng công suất tiêu thụ (kW) | 5 |

| 12 | Nguồn cấp | 380V 50Hz |

| 13 | Kích thước máy (mm) | 4000*2753*2130 |

| 14 | Trọng lượng máy (kg) | 4000 |

| 15 | Air Pressure(MPa) | 0.5-0.8 |

See the SH200-R in Action at Customer Sites

Watch how our global customers use the Extra-large quartz cutting machine in real production environments.

These on-site videos showcase the machine's slicing performance, smooth operation, and material-saving vacuum clamping system in action.

Cutting Methods for 2-Meter Diameter Optical Glass: A Practical Comparison

Cutting Methods for 2-Meter Diameter Optical Glass: A Practical Comparison

Cưa dây kim cương vô tận

Cưa dây kim cương vô tận  Recommended

Recommended

Thuận lợi:

Capable of continuously cutting large cylindrical or thick optical glass blocks

Narrow kerf (0.4–1.0 mm), minimal material loss

Delivers low-stress, chip-free, mirror-quality surfaces

Compatible with rotating workpiece setups for faster and more uniform cuts

Best For:

Oversized optical glass, quartz blocks, and radiation shielding glass with diameters >1 meter and thickness >100 mm

Multi-Wire Saw

Multi-Wire Saw  Limited

Limited

Thuận lợi: High-efficiency slicing for batch wafer production

Nhược điểm:

Fixed cutting direction; mainly for wafer-level slicing

Difficult to clamp and handle oversized blocks

Limitations: Not suitable for segmenting large-diameter glass blocks

Máy cưa vòng kim cương

Máy cưa vòng kim cương  Partially Applicable

Partially Applicable

Thuận lợi: Flexible machine structure, supports long cutting strokes

Nhược điểm:

Wide kerf, rough cutting surfaces, prone to edge chipping

Low cutting speed and efficiency

Use Case: Acceptable for coarse pre-cutting of 2-meter glass, but not suitable for high-precision applications

Abrasive Waterjet

Abrasive Waterjet  Not Recommended

Not Recommended

Limitations:

Glass is thermally sensitive; waterjet may cause microcracks

Risk of contaminating valuable glass with water and abrasive slurry

Use Case: Better suited for small composite materials, not large-diameter optical glass

Sự cắt bằng tia la-ze

Sự cắt bằng tia la-ze  Not Suitable

Not Suitable

Limitations:

Ineffective on thick optical glass

High risk of edge fracture and poor surface quality

Use Case: Not viable for optical-grade segmenting of large glass blocks

Phần kết luận:

Phần kết luận:

For cutting 2-meter diameter optical glass, the cưa dây kim cương vô tận stands out as the most reliable and effective solution.

It offers unmatched capability in terms of size compatibility, surface quality, cutting safety, and stability. This makes it ideal for high-value applications in aerospace, radiation shielding, and scientific research involving large-format optical materials.

COMPARISON OF THE CUT SURFACE EFFECT

TYPICAL APPLICATIONS OF THIS EXTRA LARGE QUARTZ CUTTING MACHINE

1️⃣ Large Quartz Crystals

Cutting oversized quartz ingots and blocks used in optics, semiconductors, and photonics

Ideal for pre-slicing high-purity materials before polishing or coating

2️⃣ Radiation Shielding Glass

Processing of leaded or high-density glass used in:

Nuclear research facilities

Medical CT or radiation shielding windows

Aerospace radiation protection systems

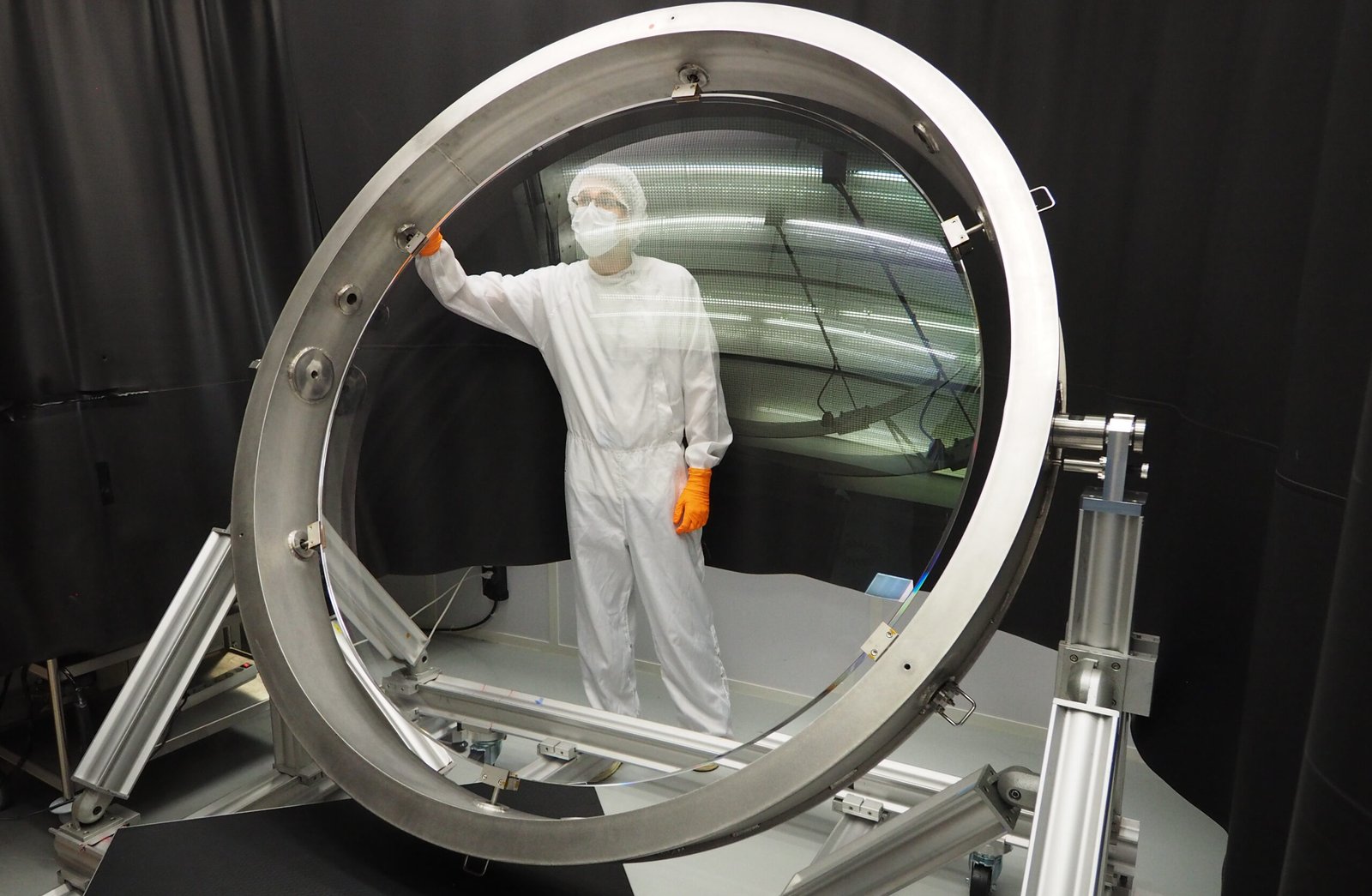

3️⃣ Aerospace-Grade Optical Components

Cutting ultra-clear, low-expansion glass materials used in:

Spaceborne optical windows

Satellite sensor shields

High-altitude reconnaissance lens blanks

4️⃣ High-Purity Ceramics & Fused Silica

Slicing large blocks of alumina, fused silica, and other engineering ceramics

Used in vacuum systems, semiconductor processing, and precision optics

5️⃣ Infrared Transparent Materials

Pre-cutting IR window materials like ZnSe substrates, sapphire, or specialty glass composites

Demands flat, clean surfaces with minimal microcracking

6️⃣ Scientific Research Materials

Institutions using SH200-R for material preparation, such as:

Large-diameter fused silica windows

Custom radiation sensor panels

Experimental shielding components

WHY CHOOSE US

High-Speed Endless Wire Cutting

High-Rigidity Cast Structure

High-Precision Guide Rails and Ball Screw

Automatic Constant-Tension System

Micron-Level Feed Control

User-Friendly Smart Interface

Fully Enclosed Protective Design (Optional)

Low Maintenance & Cost Efficiency

Modular Design

Low Maintenance & Cost Efficiency

Automatic Lubrication System

Customer Testimonials

Frequently Asked Questions

What is the maximum thickness the machine can handle for cutting?

What is the difference between this wire saw and BAND SAW?

The cutting speed would be similar, but wire saw’s cut surface quality is far more better. and the kerf loss is smaller.