1. Industry Background: Increasing Demand for Coating Integrity

With the rise of augmented reality, automotive sensing, and advanced imaging, multilayer coatings are now applied across a wide range of optical glass substrates. These coatings often involve combinations of oxide films, metal layers, and functional polymers. The cutting of such components—especially where coatings extend to the edge—introduces risk of delamination, microcracks, or thermal stress.

The industry is moving away from methods that compromise surface integrity. Among available options, cold cutting has emerged as a process requirement for many 3D optical coating cutting tasks.

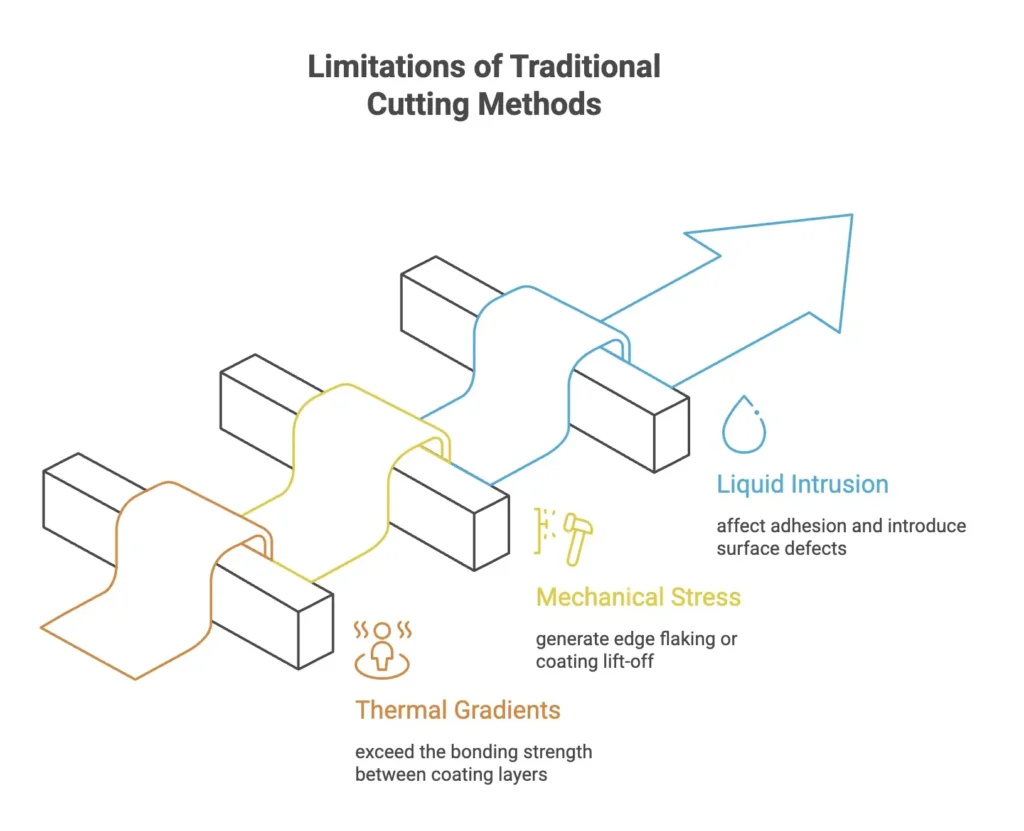

2. Limitations of Traditional Cutting Methods

High-speed mechanical sawing, laser ablation, and abrasive waterjets all share common drawbacks when applied to coated optics:

- Localized thermal gradients may exceed the bonding strength between coating layers.

- Vibration or impact during mechanical slicing can generate edge flaking or coating lift-off.

- Liquid intrusion during waterjet cutting can affect adhesion and introduce surface defects.

These failure modes are especially problematic in optics where full-aperture coatings must remain intact to preserve system performance.

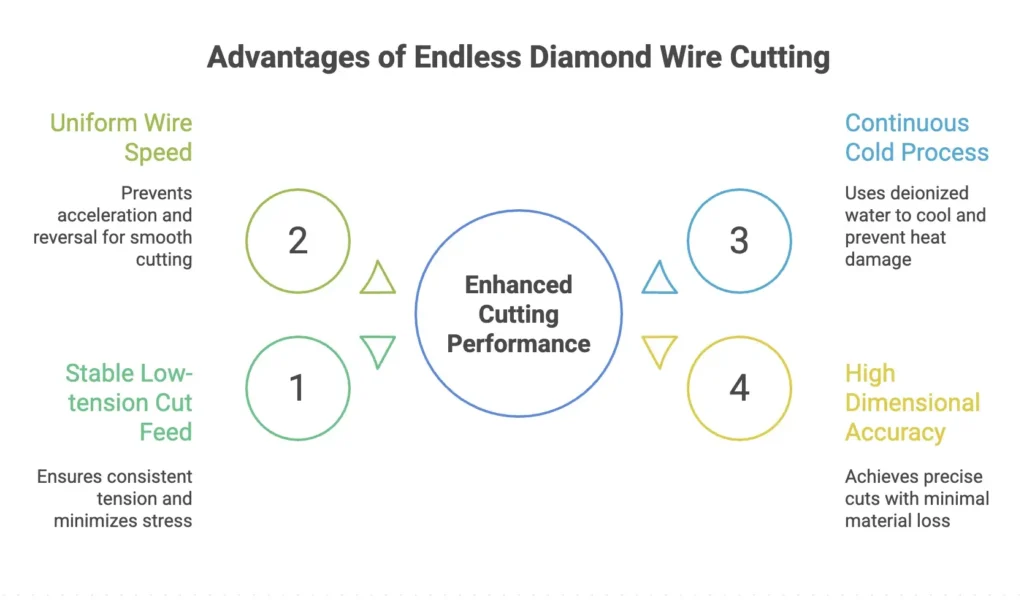

3. Process Direction: Cold Cutting with Endless Wire

In response to these limitations, manufacturers increasingly adopt dây kim cương vô tận systems for 3D optical coating cutting. This approach offers:

- Stable low-tension wire feed minimizing mechanical stress

- Uniform wire speed (no reversal or acceleration zones)

- Continuous cold process using deionized water as coolant

- High dimensional accuracy with low material loss

The key benefit lies in layer preservation. Coating adhesion and interface stability remain uncompromised, even in sub-100 μm coating stacks.

4. Alignment with Market Trends

Leading optics manufacturers have incorporated cold cutting cells in production lines for AR combiners, laser sensor windows, and diffractive elements. These cells support multi-axis control and accommodate both planar and 3D profiles.

Use cases include:

- Wafer-level optics with microstructured coatings

- Angle-cut waveplates and thin prisms

- Coated filters requiring sub-millimeter edge alignment

In each scenario, cold cutting has proven essential for maintaining coating functionality post-processing.

5. Summary

As the complexity of optical coating structures continues to rise, so does the requirement for non-destructive, cold slicing methods. Endless diamond wire has established itself as a process-compatible solution for 3D optical coating cutting, offering high yield, edge cleanliness, and coating integrity—especially in high-value or multilayer optical assemblies.