In today’s modern industries, precision cutting plays a major role in making high-quality products. Whether it is semiconductor wafers, optical glass, or ceramic materials, accurate slicing can determine the success of the final product. Among the modern cutting tools available, the advanced segment coated cutting wire loop has become a powerful choice. This innovative wire offers smooth and efficient slicing, reducing waste while keeping materials safe from damage.

Sharp Segment Coated Cutting Wire Loop

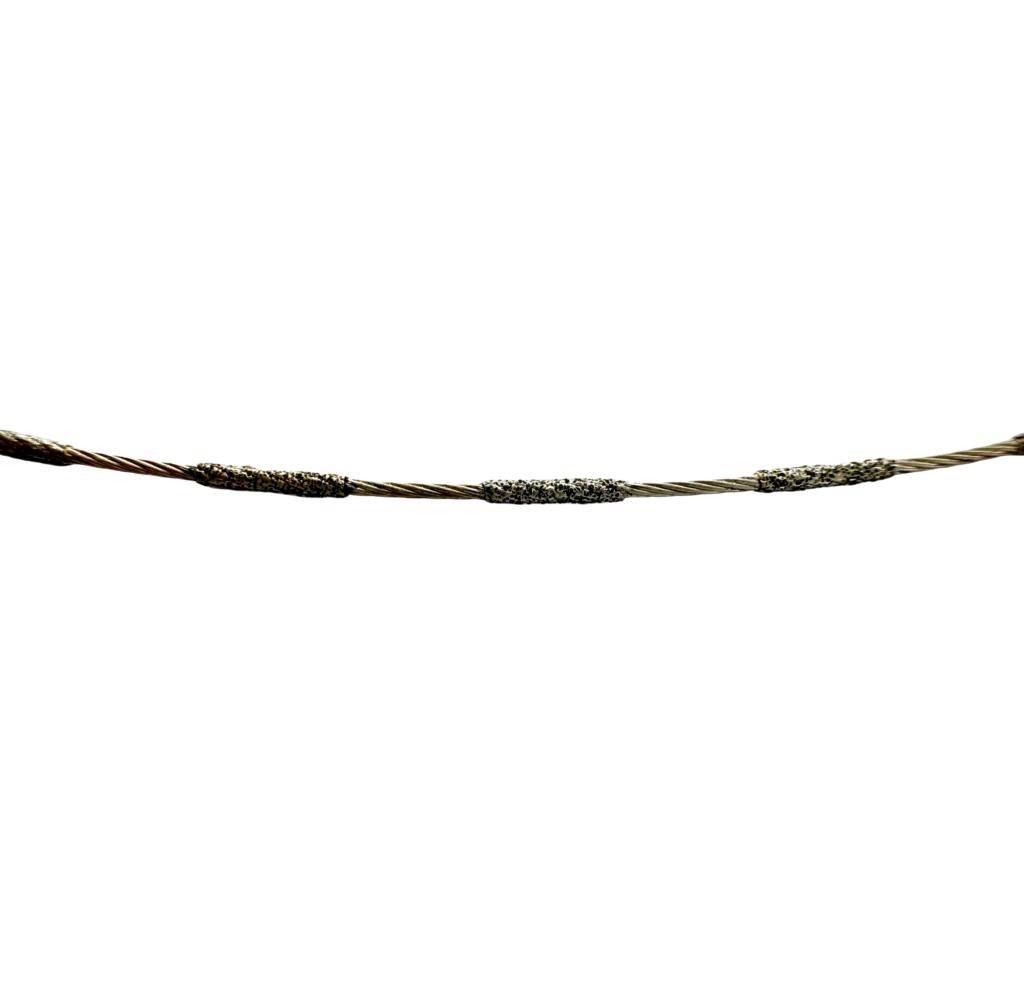

Сайт Segment coated cutting wire loop is built for smooth, sharp, and accurate cutting of ultra-hard materials. Unlike plain wires, this advanced design uses a closed-loop structure with diamond coating applied in spaced segments. This unique layout improves both precision and durability, making it one of the most efficient cutting tools available today.

In the first generation, diamond coating was spread evenly across the wire surface. While effective, it often struggled with heavy dust and debris during cutting. With the new second-generation design, the coating is divided into segments. These gaps create extra clearance for debris, preventing build-up and keeping the wire sharp. This simple but powerful improvement has increased the cutting wire’s lifespan by 30% to 50%.

Another big advantage is wire thickness. Traditional endless diamond wires are limited to about 1 mm in diameter. With the segmented coating method, the wire can now be made as thick as 3.5 mm. A thicker wire brings more strength, longer life, and better stability during demanding jobs.

Using a Segment Coated Cutting Wire Loop benefits

The biggest benefit of a segment coated cutting wire loop is precision. Traditional cutting tools may create cracks, chips, or uneven surfaces. But with coated wire loops, the process becomes smooth and consistent. Another benefit is speed. The coating on the wire enhances its sharpness and durability, which allows it to slice the hard material quickly.

Сайт diamond wire cutting loop has to reduce energy use. Since they cut with high efficiency, machines require low power to complete the same task. This means low cost and better productivity.

How Segment Coating Improves Cutting Performance

The mystery of the segment coated cutting wire loop lies in the segment coating. This coating is usually made of diamond particles, which are one of the most difficult materials on Earth. When applied to the wire surface, the coating acts like countless small cutting edges. As soon as the wire moves, these diamond fragments are accurate and pieces with the material with strength.

Without a coating, a plain wire can quickly wear out or fail to cut the rigid material. But with the segment coating, the wire maintains its cutting power for a long time. It reduces friction and heat, which means less risk of damaging the workpiece. The results are a cleaner cut, smooth edges and high-quality products.

Features of our advanced cutting wire loop

Наш сайт segment coated cutting wire loops are designed keeping in mind the needs of the industry. They come with a strong steel core that provides stability and prevents breakdown during heavy use. The segment coating is applied using the latest technology, ensuring the distribution of diamond particles along with the wire surface. This makes the wire reliable and long-lasting.

Another major feature is flexibility. The coated wire for precision cutting can handle individual cutting machines and is suitable for both high-speed and accurate cutting. It performs continuously in working hours for a long time. Our diamond wire cutting tool is tested under strict quality standards to ensure that it meets the demands of industries such as electronics, glass and ceramics. Customers can rely on these wires for smooth operation and to reduce downtime.

Materials Suitable for Segment Coated Wire Cutting

One of the best things about segment coated cutting wire loops is their ability to cut a variety of materials. They are perfect for cutting optical glass, requiring minimal lubrication. They are also widely used in cutting sapphire and quartz, both are known for their hardness and brittleness. Traditional equipment often fails with these materials, but coated wires easily handle them.

Ceramic can be cut efficiently using a coated wire loop. These ingredients are used in therapy, aerospace and electronic industries, where accuracy is non-negotiable. The high-performance cutting wire ensures clean cuts without breaking or chipping.

Application in semiconductor, glass and ceramic

The demand for segment coated wire loops in the semiconductor industry is particularly high. Wafers should be cut into thin slices with extreme accuracy. Any error can cause waste and financial loss. The wire saw for semiconductor slicing ensures that each wafer is cut properly, ensuring efficiency in chip production.

In the glass industry, these wires are used to cut optical glass, display panels and special glass products. Lubrication is important here, as small scratches can also reduce the quality of the product. The coated wire almost cuts clean with zero surface damage.

For the ceramic industry, coated wire loops provide a reliable way to cut complex shapes and delicate parts. They are also widely used in research laboratories where scientists need to cut experimental material without harm.

Segment coated wire VS traditional cutting tools

Compared to traditional devices such as saw blades or plain wires, the segment-coated diamond wire provides many advantages. They cut rapidly, live longer, and provide high accuracy. Traditional equipment often produces more heat and dust, which can damage both the machine and the material. Conversely, coated wires reduce friction and keep the process clean.

Another major reason for choosing coated wire is cost efficiency. Even though the initial investment may be slightly higher, long-term life and short waste saves money in the long run. Businesses switching to segment coated cutting wire loops improve production rates and high-quality results.

Consider when selecting the right wire cutting material

When selecting the correct cutting wire, several factors should be considered.

- The first is the hardness of the material. For extremely difficult materials such as sapphire or quartz, a high-quality diamond-layered wire loop is required.

- Think about the thickness of the material. Thick material requires a strong wire with high durability.

- It is also important to consider the speed of cutting. Some applications require rapid results, while others focus on accuracy. The right wire loop should balance both speed and precision.

- Always check the quality and reliability of the wire manufacturer. Using low-quality wires can cause material loss, downtime and damage.

Where to buy high-quality segment coating wire loops?

For businesses looking for Industrial cutting wire solutions, it is important to choose the right supplier. They are a reliable name in the region. As a high-tech manufacturer, Vimfun specialises in the diamond wire cutting solutions for optical glass, sapphire, quartz and other ultra-hard materials. Their products are developed using advanced technology and strict quality standards.

Vimfun’s segment coated cutting wire loops are known for their durability and performance. They provide customised solutions based on customer needs, making them a reliable partner for industries worldwide. With years of experience and innovation, they have become a leader in distributing top-quality wire cutting products.

Why Are Our Cutting Wire Loops the Best?

Наш сайт segment coated cutting wire loop stands out due to its strength, accuracy and long life. Each wire is prepared with advanced diamond section coating, which ensures frequent performance even in difficult conditions. We focus on distributing wires that reduce waste, improve speed, and protect the material from cracks or chips.

Unlike many contestants, we use high-grade materials and follow strict test standards. This assures our customers in every cut by they. Our wires are not only equipment, but also solutions that help businesses achieve better results. With smooth operation, low downtime, and excellent cutting efficiency, our hard material cutting loops are trusted by professionals in various industries. This is why our cutting wire loops are the best option for anyone who places importance on quality and performance.

Вопросы и ответы

What is a segment coated cutting wire loop?

It is a wire loop coated with diamond segments that are designed for smooth and accurate cutting of hard materials.

Which materials can be cut with it?

It can cut sapphire, quartz, optical glass, ceramic and other ultra-hard materials.

Why is the segment coating important?

The coating improves cutting speed, accuracy and durability compared to plain wires.

Where are the segment-coated wire loops used?

They are widely used in semiconductors, glass and ceramic industries.