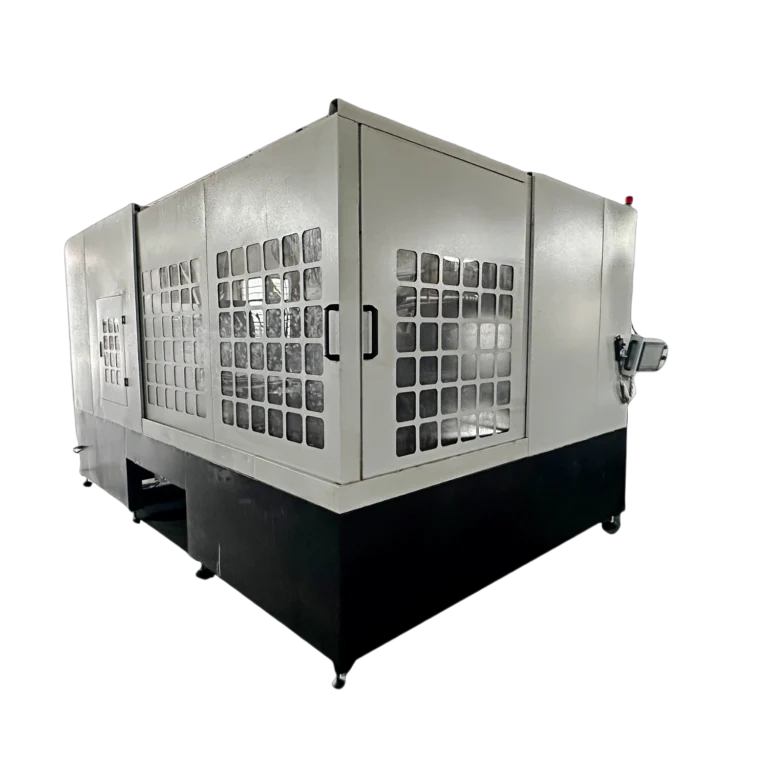

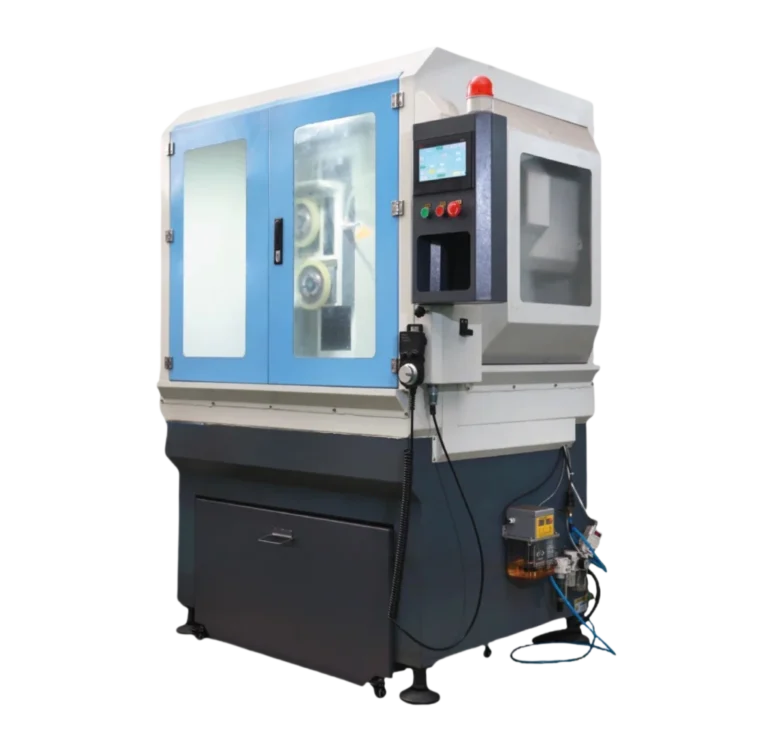

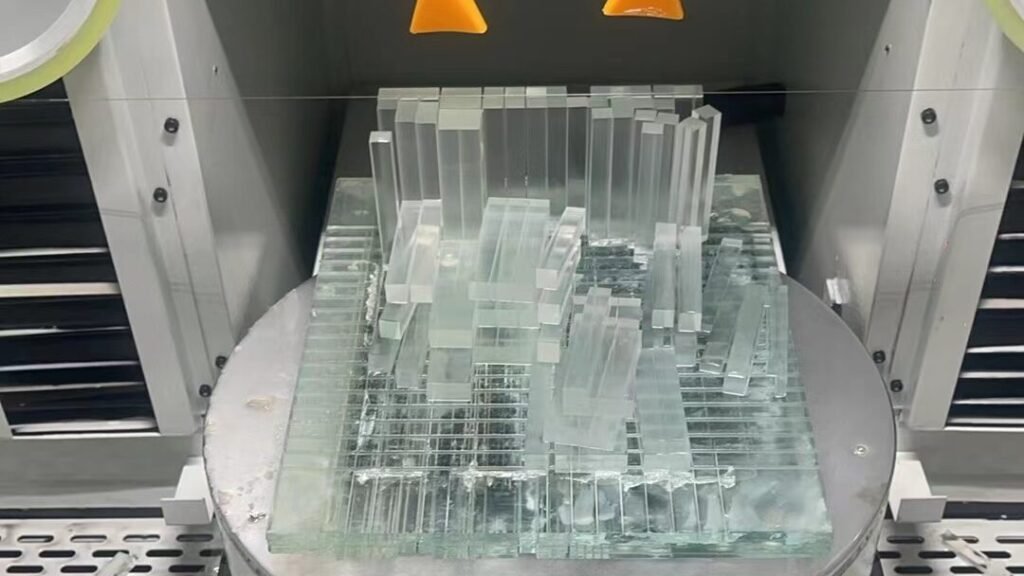

Cutting optical glass, such as K9, germanium, and Schott glass (e.g., BK7), demands precision and care to achieve flawless surfaces for lenses and prisms. The VIMFUN Precision Optics Cutting Machine, featuring a ring-shaped diamond wire, delivers exceptional accuracy (0.03 mm tolerance) and versatility for lenses from 1 mm to 3 meters in diameter and 0.1 mm to 1 m in thickness. With high-speed cutting (up to 80 m/s) and automation features, this machine is ideal for optical shops and labs. This article outlines the best practices for cutting optical glass using the Precision Optics Cutting Machine, ensuring high-quality results and addressing key concerns like surface quality and efficiency.

1. Prepare the Glass and Substrate Thoroughly

Proper preparation sets the foundation for successful cutting:

- Clean Surfaces: Wipe the optical glass (K9, germanium, or Schott) and substrate (glass or stainless steel) with isopropyl alcohol to remove dust and oils, ensuring strong glue adhesion and preventing defects.

- Inspect the Glass: Check for scratches or coating damage, especially on germanium, to avoid compromising optical performance.

- Choose a Stable Substrate: Select a flat substrate to minimize vibration, leveraging the Precision Optics Cutting Machine’s 0.03 mm precision for consistent results.

2. Select the Optimal Glue

Glue selection is critical for securing optical glass during high-speed cutting:

- Recommended Glue: Use UV-curable glue like Norland NOA68 for its strong bonding and clean peeling. Apply a 0.1-0.2 mm layer to the substrate, press the glass gently to avoid air bubbles, and cure with UV light (365 nm, 5-30 seconds).

- Материальные соображения: For germanium, prioritize hot water peeling (60-80°C) to protect coatings, avoiding harsh solvents like acetone. For K9 and Schott glass, NOA68 resists oil-based coolants and ensures residue-free removal.

- Benefits: The glue’s compatibility with the Precision Optics Cutting Machine’s high-speed (up to 80 m/s) and low-vibration design prevents lens displacement and maintains optical clarity.

3. Optimize Machine Settings

Configure the Precision Optics Cutting Machine for specific glass types:

- Скорость провода: Set the ring-shaped diamond wire to 10-30 m/s for germanium (brittle) and 20-50 m/s for K9 or Schott glass, balancing precision and smoothness. Use higher speeds (up to 80 m/s) for thicker lenses (up to 1 m).

- Особенности автоматизации: Utilize auto-slicing and tilt functions for complex cuts, reducing manual adjustments and ensuring consistency for custom optics.

- Coolant Choice: Opt for dry cutting to leverage the machine’s eco-friendly design, saving up to 1 million liters of water annually. For oil-based coolant, activate the coolant recycling system to minimize waste.

4. Monitor the Cutting Process

- Maintain Precision: Monitor wire tension to ensure the Precision Optics Cutting Machine maintains its 0.03 mm tolerance, delivering chip-free edges for high-clarity optics.

- Control Temperature: Keep temperatures below 300°C for germanium to avoid thermal stress, using the mist recovery system to manage heat and debris.

- Adjust for Size: Configure settings for lens sizes from 1 mm to 3 meters, supporting diverse applications from micro-lenses to large optical components.

5. Post-Cutting Cleaning and Inspection

- Peel the Glue: Remove NOA68 with hot water (60-80°C, 5-10 minutes) or heat (80-100°C) to avoid residue, especially on germanium coatings.

- Clean the Surface: Use ultrasonic cleaning (deionized water or isopropyl alcohol, 5-10 minutes, 40 kHz), followed by plasma cleaning (oxygen or argon, 2-5 minutes) for germanium to ensure optical clarity.

- Inspect Edges: Verify cuts meet the 0.03 mm tolerance and are free of defects, ready for polishing or coating.

Benefits of Best Practices with the VIMFUN Precision Optics Cutting Machine

Following these practices with the VIMFUN Precision Optics Cutting Machine ensures:

- Superior Quality: 0.03 mm precision for K9, germanium, and Schott glass optics.

- Эффективность: Automation streamlines production for small shops and large labs.

- Sustainability: Dry cutting and coolant recycling align with eco-friendly trends.

- Универсальность: Handles diverse materials and lens sizes for various applications.

Заключение

By adopting these best practices, you can maximize the VIMFUN Precision Optics Cutting Machine’s performance for cutting optical glass, delivering precision and efficiency. From preparation to post-cutting cleaning, this machine ensures high-quality results for optical shops and labs. Visit www.opticalcutting.com to learn how the VIMFUN Precision Optics Cutting Machine can enhance your optical manufacturing process.