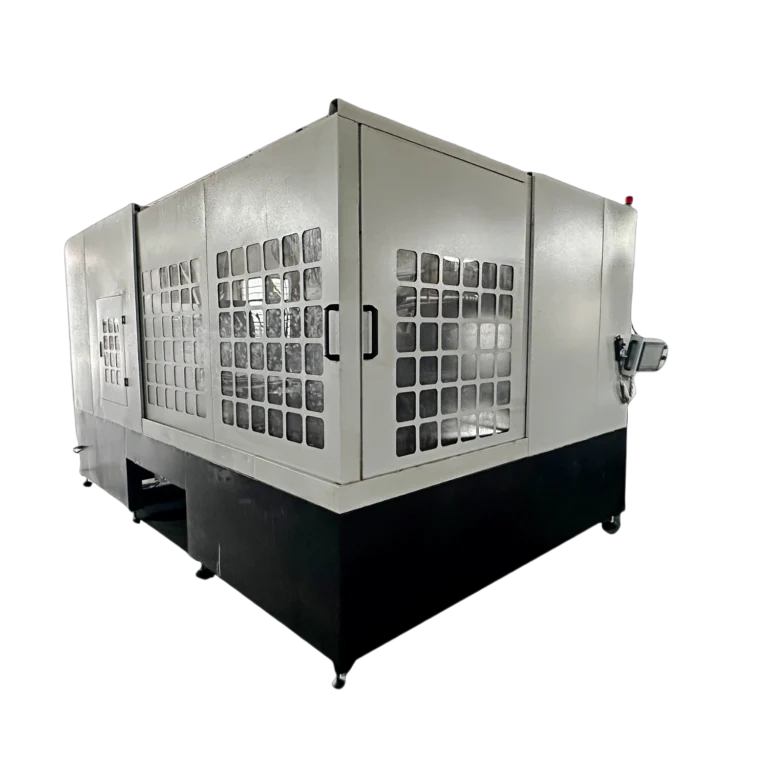

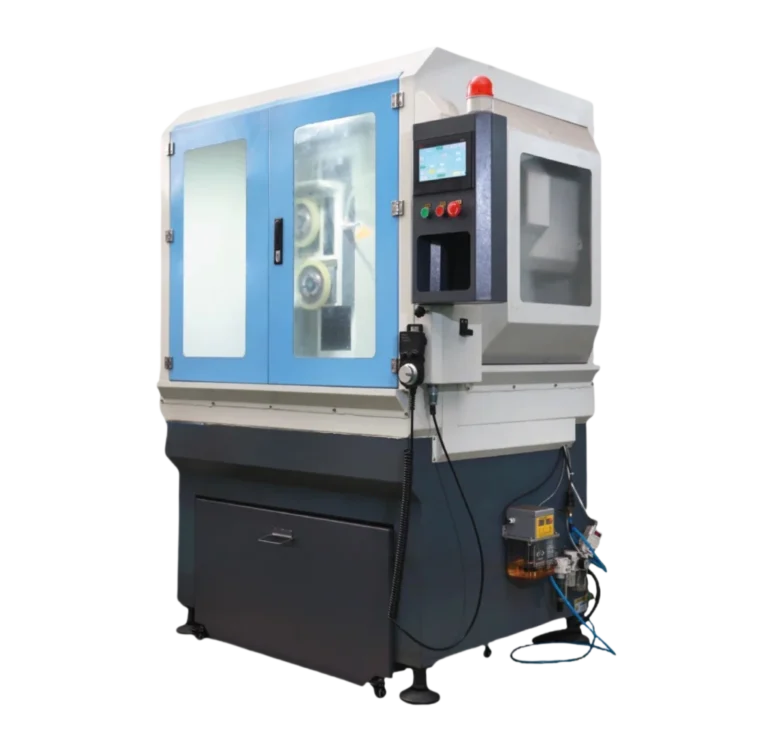

Advanced CNC Endless Diamond Wire Saw–Smooth & Efficient Cutting

Cutting Ultra-Hard materials has always been a challenge for industries that work with glass, sapphire, ceramic and quartz. Traditional cutting appliances often fail because these materials are brittle and delicate. They can crack, chip, or break under pressure. This is why modern industries rely on advanced equipment such as CNC endless diamond wire. This machine combines computer numerical control (CNC) technology with a continuous loop of diamond-coated wire. The result is smooth, accurate and highly efficient cutting. From optical glass to semiconductor, the CNC Endless Diamond Wire Saw is now one of the most reliable solutions for accurate slicing. Why Choose CNC Endless Diamond Wire Saw? When cutting the ultra-hard and brittle material, accuracy matters more than anything. Even a small crack or uneven cut can ruin an expensive part. This is where CNC endless Diamond Wire showed its strength. Unlike traditional saws, it uses an endless loop of coated