Optical shops, whether small-scale or part of large manufacturing labs, face increasing pressure to deliver high-precision lenses efficiently while managing costs. The VIMFUN Optical Lens Cutting Equipment, with its advanced ring-shaped diamond wire design and automation features, offers a transformative solution for optical shops cutting K9 glass, germanium glass, and Schott glass (e.g., BK7). This article explores why investing in this automated Optical Lens Cutting Equipment is a game-changer, highlighting its productivity, scalability, and alignment with the industry’s shift toward automation, as seen in the projected 9.2% CAGR growth of the optical lens cutter market through 2032.

The Need for Automation in Optical Shops

Traditional optical cutting methods, such as manual blade edgers or semi-automated laser systems, often lead to bottlenecks in production, high labor costs, and inconsistent quality. X discussions in r/Optics and r/CNC emphasize the demand for automated solutions that streamline workflows and reduce errors, especially for small shops handling custom orders. The VIMFUN Optical Lens Cutting Equipment addresses these challenges with cutting-edge automation, making it an ideal investment for optical shops seeking to boost efficiency and competitiveness.

Key Benefits of the VIMFUN Optical Lens Cutting Equipment

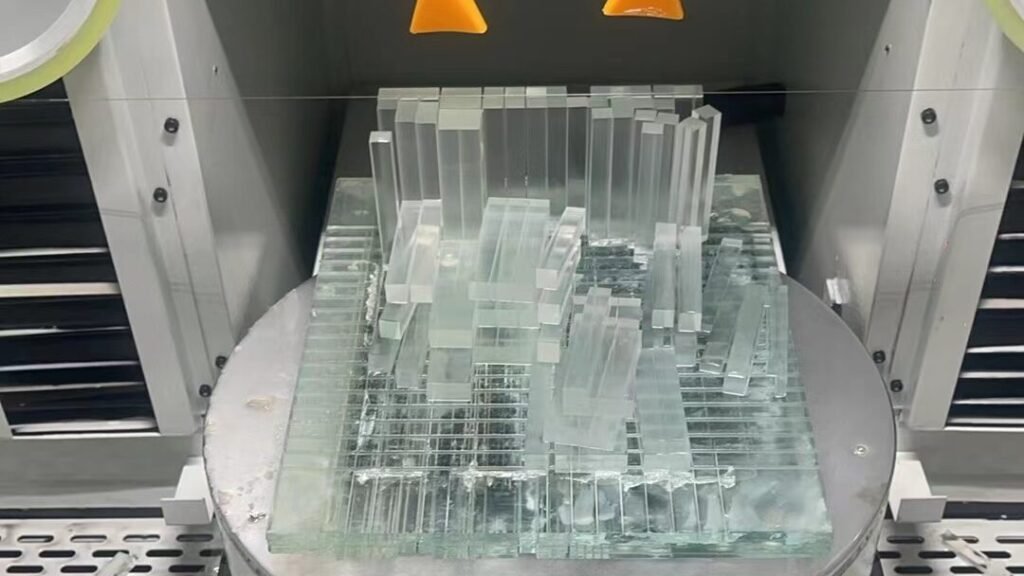

그만큼 Optical Lens Cutting Equipment leverages a ring-shaped diamond wire, operating at speeds from 0 to 80 m/s, to deliver precision and productivity. Its key features include:

- Advanced Automation: Features like auto-slicing, complex shape cutting, and a tilt function enable the equipment to handle intricate lens designs with minimal operator input. This automation reduces setup time and human error, ideal for high-volume or custom orders in optical shops.

- High Precision and Speed: With a cutting tolerance of 0.03 mm and wire speeds up to 80 m/s, the equipment ensures micron-level accuracy and smooth surfaces for K9, germanium, and Schott glass. The unidirectional wire motion minimizes chipping, delivering optical-grade lenses for applications like infrared optics.

- Scalability for All Shop Sizes: Available in tabletop and large-scale versions, the equipment supports lenses from 1 mm to 3 meters in diameter and 0.1 mm to 1 m in thickness, catering to both small shops and industrial labs. This flexibility addresses X user needs for versatile machines.

- 비용 효율성: By minimizing material waste and automating workflows, the equipment reduces operational costs, making it a cost-effective choice for shops aiming to maximize profitability.

Eco-Friendly and Low-Maintenance Design

그만큼 VIMFUN Optical Lens Cutting Equipment aligns with sustainability trends by supporting dry cutting, eliminating water usage (saving up to 1 million liters annually compared to traditional systems). For clients using oil-based coolants, its recycling system and mist recovery technology reduce waste and protect air quality, as highlighted in industry reports. The equipment’s low-maintenance design, with features like automated wire tension adjustments, minimizes downtime, ensuring consistent performance for busy optical shops.

Glue Compatibility for Enhanced Productivity

To secure lenses during cutting, the Optical Lens Cutting Equipment pairs seamlessly with UV-curable glues like Norland NOA68, tailored to material characteristics. This glue:

- Ensures Stability: Holds lenses firmly during high-speed cutting, preventing displacement.

- Peels Cleanly: Removes with heat (80-100°C) or hot water/isopropyl alcohol, avoiding residue on sensitive germanium coatings, a key concern in r/CNC discussions.

- Supports Automation: Fast curing (5-30 seconds) complements the equipment’s automated workflows, speeding up production.

This compatibility enhances productivity, allowing shops to maintain high throughput without compromising quality.

Why Invest in the VIMFUN Optical Lens Cutting Equipment?

Investing in the VIMFUN Optical Lens Cutting Equipment offers optical shops:

- Increased Productivity: Automation reduces labor and speeds up custom lens production.

- Precision Excellence: 0.03 mm tolerance ensures high-quality cuts for diverse optical materials.

- Scalability: Tabletop and large-scale options suit small shops and large labs.

- Sustainability: Dry cutting and coolant recycling lower environmental impact.

- 비용 절감: Reduced waste and maintenance costs boost profitability.

결론

그만큼 VIMFUN Optical Lens Cutting Equipment empowers optical shops to meet modern demands with its automated, precise, and eco-friendly design. By streamlining production and ensuring flawless cuts for K9, germanium, and Schott glass, it’s a smart investment for shops aiming to stay competitive. Visit www.opticalcutting.com to discover how the VIMFUN Optical Lens Cutting Equipment can elevate your optical shop’s efficiency and success.