SGS180-90

The SGS180-90 is an industrial-grade diamond wire cutting machine designed for ultra-large optical glass blocks, particularly high-purity quartz. With a cutting capacity of up to 1800 mm in length,900 mm in width and 600 mm in height, this machine is ideal for large-format material processing in research institutes and industrial glass production lines.

Key Features of SGS180-90

Purpose-Built for Oversized Quartz Blocks

Engineered specifically for cutting ultra-large quartz glass materials up to 1800 mm in length and 900 mm in width and height, including high-purity blocks used in optical and semiconductor industries.

Oscillating Endless Diamond Wire Cutting

Equipped with a top-down cutting system that integrates high-speed endless diamond wire 그리고 lateral oscillation, enabling smooth slicing with built-in polishing effect. This results in reduced surface roughness and minimal subsurface damage.

High-Speed Cutting with Clean Surface Finish

The oscillating motion increases cutting efficiency and produces mirror-like surfaces, eliminating the need for secondary polishing in many applications.

Scalable Structure for Extra-Large Loads

Thanks to the scalable gantry structure and adjustable stroke, the SGS180-90 can handle heavy and oversized blocks with no compromise in cutting quality or mechanical stability.

Side-Open Work Area for Easy Loading

Designed with an open-sided loading platform, enabling crane or forklift access to place large glass blocks easily and safely.

Customizable Clamping System

Supports integration of magnetic fixtures, vacuum chucks, or custom mechanical holders for securing large and heavy optical materials during slicing.

Low Kerf Loss and Precision Control

Delivers narrow kerf widths (0.4–0.6 mm) with highly repeatable parallel cuts. Ideal for applications where material conservation and cut uniformity are critical.

Fully Programmable Control System

The touchscreen interface allows users to adjust wire speed, oscillation amplitude, stroke, and cutting cycles for batch or prototype production with consistent results.

Stable and Low-Stress Cutting

The abrasive, oscillating motion combined with vertical top-down feeding produces ultra-low cutting force, preventing edge chipping, internal fractures, or material shift.

SVS180-90 TECHNICAL SPECIFICATION

| 아니요. | 이름 | 사양 |

| 1 | 최대 공작물 길이(mm) | 1800 |

| 2 | 최대 공작물 폭(mm) | 900 |

| 3 | 최대 공작물 높이(mm) | 600 |

| 4 | 작업대 Y축 이동(mm) | 1800 |

| 5 | 작업대 Z축 이동(mm) | 900 |

| 6 | 최대 다이아몬드 와이어 속도(m/s) | 84 |

| 7 | 최소 이송 증가량 Y축(mm) | 0.01 |

| 8 | 최소 이송 증가량 Z축(mm) | 0.01 |

| 9 | 반복 위치 정확도 Y축(mm) | 0.01 |

| 10 | 반복 위치 정확도 Z축(mm) | 0.01 |

| 11 | 총 소비전력(kW) | 4 |

| 12 | 전원공급장치 | 220V 50Hz |

| 13 | 기계크기(mm) | 2900*2000*2600 |

| 14 | 기계중량(kg) | 3800 |

| 15 | 기압(MPa) | 0.5-0.8 |

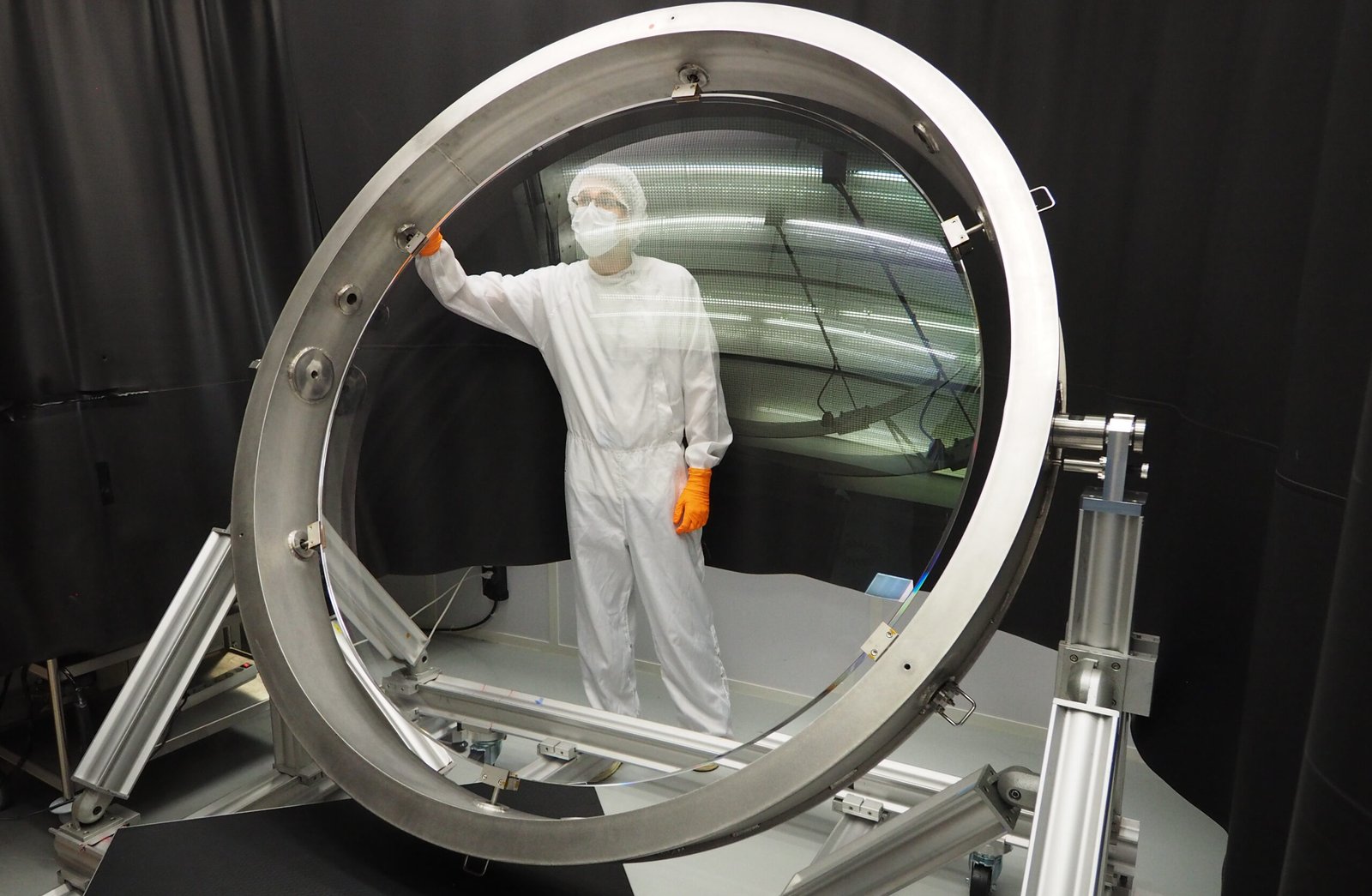

See the SGS 180-90 in Action at Customer Sites

COMPARISON OF DIFFERENT CUT METHOD

industrial glass processors. Traditional cutting technologies often fall short when faced with blocks measuring up to 1800 mm in length and 900 mm in both width and height. The SGS180-90 diamond wire saw by Vimfun provides a purpose-built, scalable solution where other technologies cannot compete.

The Other Machines Are Commonly Used?

The Other Machines Are Commonly Used?

1. Multi-Wire Saw

Pros: High-efficiency slicing for wafer production

Cons:

Limited to fixed parallel slicing only

Complex, high-maintenance system with expensive consumables

Poor compatibility with irregular block sizes

Difficult clamping and alignment

2. Inner Diameter Saw (ID Saw)

Pros: Precision slicing for small, thin wafers

Cons:

Limited to workpieces under 300 mm

Unsuitable for large or thick quartz blocks

3. Diamond Band Saw

Pros: Long cutting stroke, low-cost equipment

Cons:

Cuts are rough and often inaccurate

Wide kerf (>1 mm) and low repeatability

High vibration and low stability for optical materials

4. EDM Wire Cut

Not applicable: Cannot be used for non-conductive materials like quartz.

Why SGS180-90 Is Superior

Why SGS180-90 Is Superior

| 기능 | SGS180-90 | Multi-Wire Saw | Band Saw | ID Saw |

|---|---|---|---|---|

| Max Workpiece Size |  (1.8m x 0.9m x 0.9m) (1.8m x 0.9m x 0.9m) |  제한적 제한적 |  Support frame needed Support frame needed |  Too small Too small |

| 표면 품질 |  Cut + grind in one Cut + grind in one |  Rough, needs polishing Rough, needs polishing |  Poor Poor |  Smooth Smooth |

| Cutting Flexibility |  Top-down, programmable Top-down, programmable |  Fixed direction Fixed direction |  Flexible stroke Flexible stroke |  제한적 제한적 |

| 커프 폭 | 0.4–0.6 mm | 0.1–0.3 mm | >1 mm | 0.3–0.6 mm |

| Operating Cost | 중간 | Very High | 낮은 | 중간 |

| 사용 편의성 | 높은 | Complex | 낮은 | 중간 |

Final Verdict

Final Verdict

The SGS180-90 offers an unmatched combination of large-format cutting capacity, oscillating diamond wire technology, and surface quality control. It is the ideal machine for cutting oversized quartz blocks used in optics, semiconductors, and research applications. Where other machines require compromise, SGS180-90 delivers precision, efficiency, and scale without limitation.

Vimfun — Cut Bigger. Cut Better.

INDUSTRIES THAT BENEFIT FROM THE SGS180-90

1️⃣ Optical Fiber Preform Manufacturing

Used for cutting high-purity quartz blocks as raw material for fiber preforms

Subsequent drawing into optical fibers

Requires long-stroke, low-stress slicing — a perfect match for the SGS180-90

2️⃣ IR Window & Optical Glass Fabrication

Processes large quartz blocks into IR windows and optical lens blanks

Demands high surface quality with zero chipping or microcracking

SGS180-90 provides clean, mirror-like cuts without secondary processing

3️⃣ Semiconductor Equipment Material Processing

Quartz is widely used for process chambers, tubes, and wafer carriers

Large quartz ingots must be cut into manageable sizes for CNC machining or polishing

Consistency and edge integrity are critical

4️⃣ Scientific Research and Material Preparation

Institutes and universities often need custom-sized quartz pieces for experiments

SGS180-90 enables high-efficiency rough cutting and sample preparation with minimal waste

5️⃣ Fused Silica Casting and Component Manufacturing

Cuts bulk fused silica ingots into usable blocks for component machining

Stable cutting with SGS180-90 improves production flow and downstream precision

6️⃣ Aerospace and Specialty Optics

Supports cutting of large, non-standard quartz glass used in aerospace IR windows, optical bases, and sensor housings

Ideal for applications where size, clarity, and stress control are essential

WHY CHOOSE US

High-Speed Endless Wire Cutting

High-Rigidity Cast Structure

High-Precision Guide Rails and Ball Screw

Automatic Constant-Tension System

Micron-Level Feed Control

User-Friendly Smart Interface

Fully Enclosed Protective Design (Optional)

Low Maintenance & Cost Efficiency

Modular Design

Low Maintenance & Cost Efficiency

Automatic Lubrication System

고객 후기

Semiconductor : Quartz Solutions

자주 묻는 질문

기계가 절단할 수 있는 최대 두께는 얼마입니까?

이 와이어 쏘와 밴드 쏘의 차이점은 무엇인가요?

절단 속도는 비슷하지만 와이어 톱의 절단 표면 품질이 훨씬 더 우수하고 커프 손실이 더 적습니다.