What Makes the Ring-Shaped Diamond Wire Optical Glass Cutting Machines Unique?

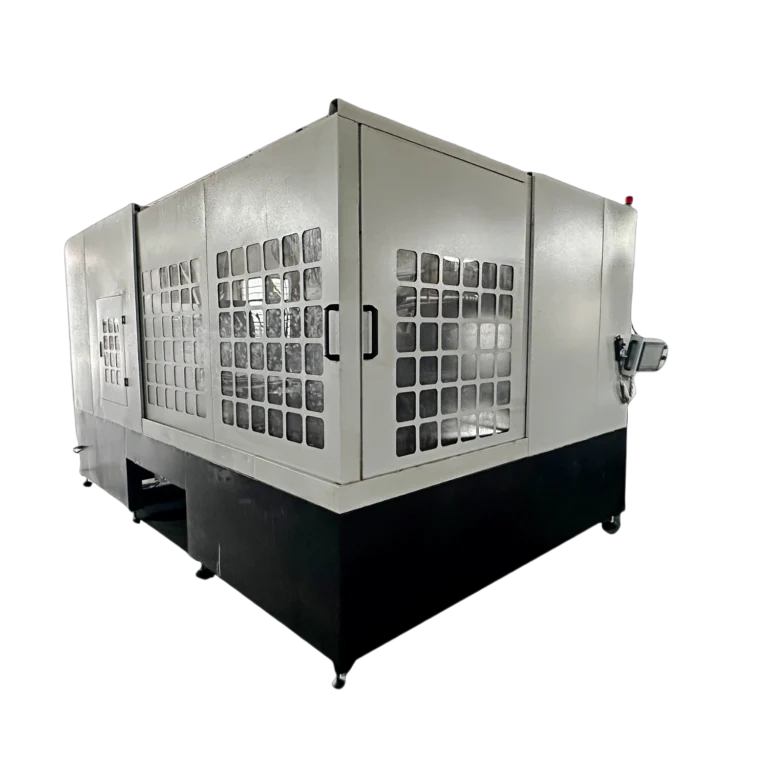

In the competitive world of optical manufacturing, the VIMFUN Optical Glass Cutting Machines stand out with its innovative ring-shaped diamond wire design, redefining precision and efficiency for cutting K9 glass, germanium glass, and Schott glass (e.g., BK7). With a wire speed range of 0-80 m/s, a cutting tolerance of 0.03 mm, and the ability to handle lenses from 1 mm to 3 meters in diameter and 0.1 mm to 1 m in thickness, this machine offers unmatched versatility. This article explores what makes the Optical Glass Cutting Machines unique, highlighting its advanced features, automation, and eco-friendly design that set it apart from traditional blade and laser cutters. Innovative Ring-Shaped Diamond Wire Design The VIMFUN Optical Glass Cutting Machines leverages a ring-shaped diamond wire, a significant departure from linear wire or blade systems. This continuous-loop design ensures: This unique design addresses industry demands for precision and efficiency, as seen in the