Glass is one of the most widely used materials in the world. From Windows and mirrors to smartphones and optical devices, glass plays a huge role in modern life. But working with glass is not easy. This requires devices that can cut with accuracy, strength and care. This is where the oscillating wire glass cutter comes. This machine de découpe de fil diamanté is designed to handle the most delicate glass cutting jobs while being strong enough for industrial use. With high accuracy and advanced design, it has become an essential tool for industries that rely on cutting clean and accurate glass.

How an Oscillating Wire Glass Cutter Works

Un oscillating wire glass cutter uses a thin diamond-coated wire that oscillates back and forth at a very fast speed. The wire oscillation speed allows it to cut through the glass easily without applying too much pressure. Unlike traditional cutting methods, which can cause cracks or rough edges, this machine ensures a clean and accurate cut.

The coating of diamonds on the wire gives it the strength to handle very difficult types of glass. As the wire moves, it slices through the material with high accuracy, reduces waste and smooths the glass surface. The glass slicing equipment is also designed to reduce vibration, which helps prevent delicate material from breaking during the procedure.

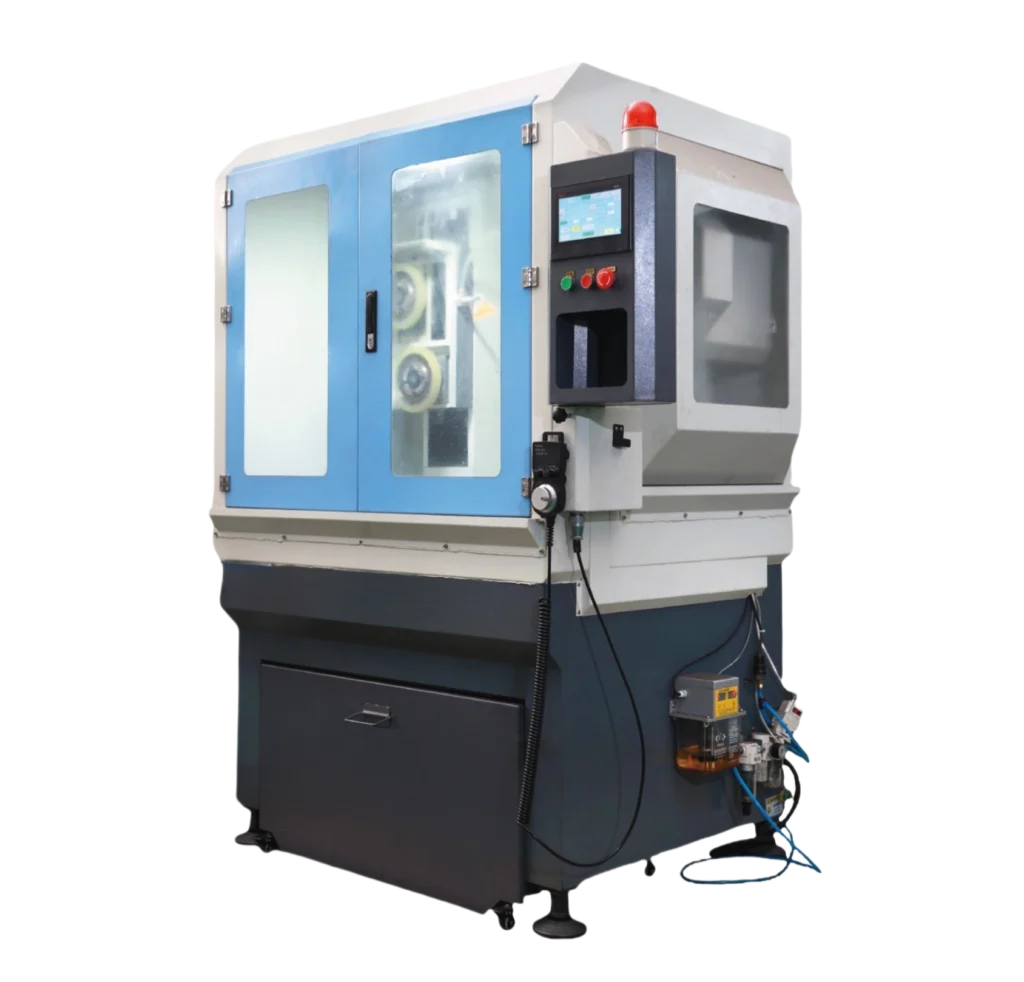

Premium Oscillating Wire Glass Cutter (SGSM 40)

SGSM 40 is a vertical endless diamond wire cutting machine designed to slice secondary for rigid and brittle materials such as sapphire, alumina, quartz and ceramics. Its vertical cutting speed provides a dual-action effect, jointly with a programmable wire swing that is both cut and polished simultaneously. This ensures a smooth surface finish by increasing the throughput for industrial production.

Swing-Wire Cutting for Flawless Surfaces

The machine’s Z-axis wire motion includes programmable oscillation. This swing action acts like a polishing tool, which reduces the edge chinging and produces clean, similar surfaces. It is particularly useful for delicate and brittle material that requires accurate handling.

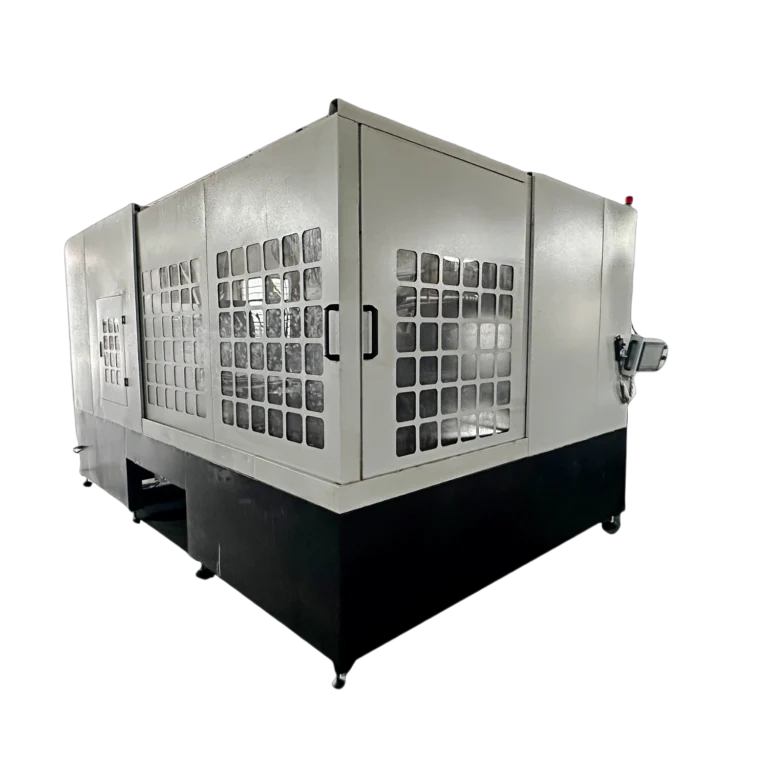

Robust Gantry Design and Safety Features

The vertical gentry structure guarantees mechanical stability and high cutting accuracy. A fully enclosed cabinet provides a safe working environment, controlling dust and debris, which makes the machine suitable for high-speed operations.

Smart control and high-speed performance

Operators can easily set parameters such as wire speed, swing degrees, and feed speed through a touchscreen or a handheld remote. The electroplated diamond wire runs at a speed of up to 38 meters/second, operated by a 2100 rpm motor, providing rapid, accurate and stable cutting.

Efficient Cooling and Lubrication

An integrated water recycling and automatic oil lubrication system keeps the surfaces clean, protects the wire, and the machine extends the lives of components.

Why Precision Matters in Glass Cutting

Glass is a delicate material, and even the smallest mistake can ruin an entire piece. Accuracy is not only a luxury but a requirement in glass cuttings. For example, in the electronics industry, glass is used in smartphones, tablets and display panels. These products demand innocent cuts, as a small crack can also affect the quality and durability of the final product.

In architecture, large glass panels are often used for windows and aspects. Cutting these panels requires accurate measurement, as any error can lead to waste and increased costs. Research also matters in laboratories, where glass is used in optical devices, medical devices, and other scientific devices. An oscillating wire glass cutter provides the level of accuracy required in all these cases.

Features of Our Precision Wire Cutter

Le oscillating wire glass cutter stands out because of the unique properties that make it more reliable and effective than traditional machines. One of the most important properties is its diamond-coated wires, which provide excellent durability and strength. This allows it to be cut easily through ultra-chilled glass.

Another important function is a low-work design. This ensures the stability of the cutting process, which is especially important when working with delicate glass sheets or complex forms. The machine à couper le saphir is also made with an advanced control system that allows users to adjust the cutting speed and accuracy.

The cooling system is often integrated into these machines to prevent overheating. The heat can damage the glass and reduce accuracy, so this function ensures safe and efficient operation.

Benefits of Using an Automated Glass Cutting System

The benefits of using an oscillating wire glass cutter are far ahead of accuracy.

- A large waste of benefits is reduced. Because the cuts are clean and accurate, the probability of breaking the glass during the process is less likely. It saves money and increases productivity.

- Another benefit is versatility. The machine can cut a variety of glasses from standard flat panels to ultra-chilling materials such as quartz and sapphire. This makes it useful for many industries.

- Efficiency is also an important advantage. With high-speed advanced designs and cuts, businesses can still complete projects while maintaining the quality.

Advanced technology in Oscillating Wire Glass Cutter

Modern oscillating glass cutters are not just machines; They are the result of many years of technological innovation. Advanced sensors and control systems enable accurate adjustment during cutting. This ensures that each cut meets the exact specifications.

Computer-Aided Design (CAD) and automation are also integrated into modern machines. This allows operators to program complex intersection patterns, which makes it possible to achieve shapes and designs that would be impossible with manual methods.

Another progress is the use of environmentally friendly systems. Many machines now come with water or cooling systems, which reduce waste and protect the environment. Energy-capable engines also reduce operating costs.

All of these technologies make the ceramic cutting tools of modern oscillations smarter, faster and more reliable than ever. They help companies remain competitive in industries where accuracy and efficiency are needed.

Choose a high-speed wire saw for your business

Choosing the right glass cutting depends on your business needs. The first thing to consider is the type of glass you work with. If you treat ultra-cut materials such as quartz or sapphire, you need a high-power machine.

Then you can think about the size of the glass you usually cut. Large sheets require a machine with a large cutting capacity, while small, detailed work may require more accurate control functions. Efficiency is another important factor. Automatic control and a high cutting machine can save time and labour costs.

You should also consider durability and maintenance. A strong and well-produced machine will last a long time and reduce shutdowns. Finally, always look for a reliable supplier that can not only provide the machine, but also provide support, training and spare parts.

Reliable Manufacturer of Oscillation Wire Glass Cuts

When it comes to a reliable oscillating wire glass cutter, a name stands out: Vimfun. They are a high-tech manufacturer that specialises in cutting solutions for diamond wire for optical glass, sapphire, quartz and other ultra-hard materials. With complete research and development as well as production skills, Vimfun ensures that each machine meets the highest standards for quality and innovation.

Their machines are trusted by research institutes and industry leaders worldwide. Known for accurate, skilled and clean cutting tools, they have earned a reputation as a global leader in the region. By choosing Vimfun, businesses not only get a machine, but also a partner who provides support, knowledge and advanced technology for long-term success.