Horizontal Endless Diamond Wire Cutting Machine for Smooth Cut

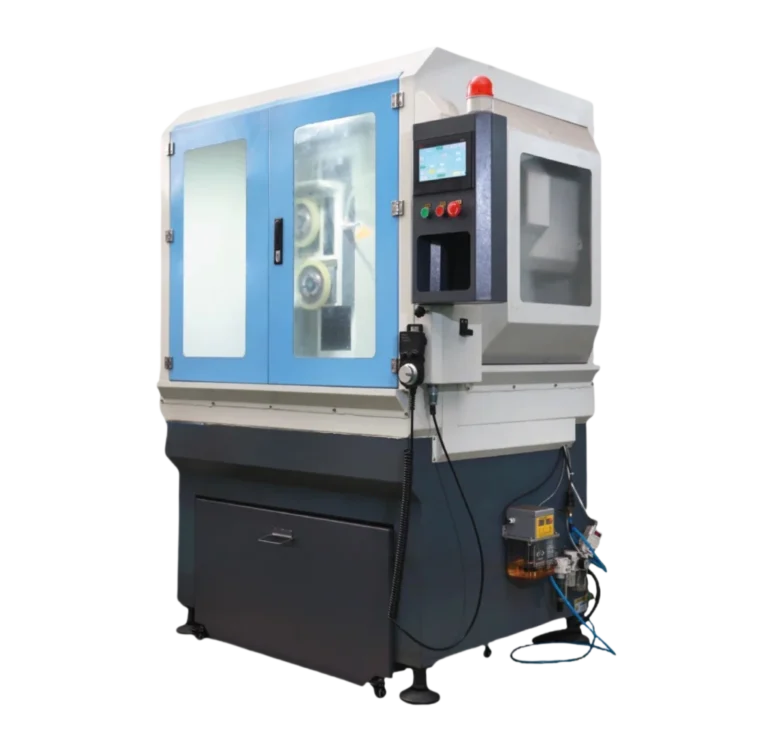

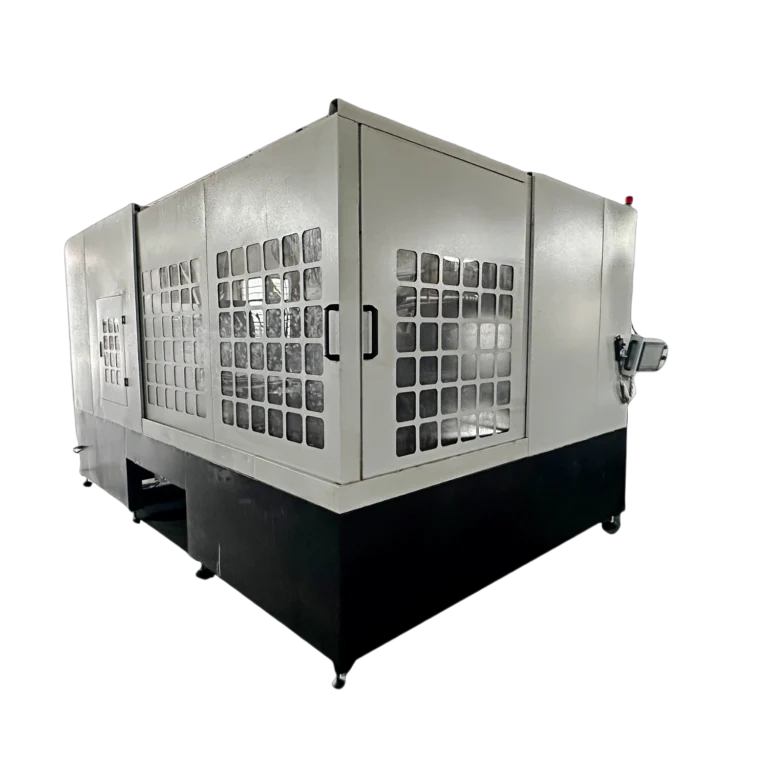

Cutting very hard materials has never been easy. Things like sapphire, quartz, and optical glass can break or crack if the wrong tool is used. Old cutting methods often waste materials and leave rough edges. For industries that need clean and accurate cuts, this is a big problem. The Horizontal Endless Diamond Wire Cutting Machine is a smart solution. It cuts smoothly, saves materials, and makes the process faster. Many industries now use this machine because it gives better results with less effort. We’ll explain what this machine is, how it works, its key features, and the benefits it brings. We will also look at its uses in different industries and why choosing a trusted maker like Vimfun is the right choice. Premium Horizontal Endless Diamond Wire Cutting Machine The SH200-R horizontal wire cutting machine is a high-performance solution made for oversized and brittle materials. It is widely used for