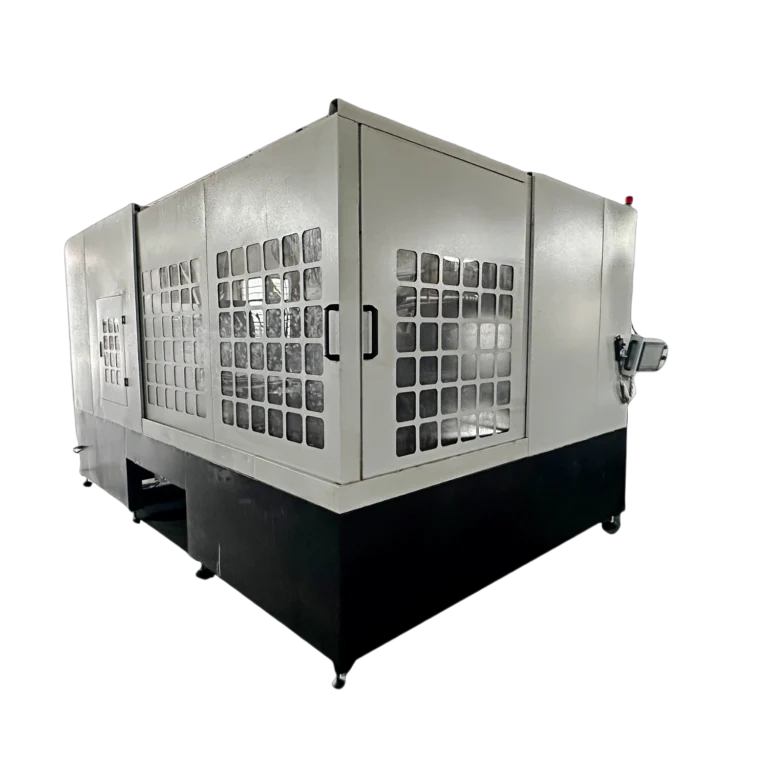

High Performance Industrial Prism Cutting Machine Exporter

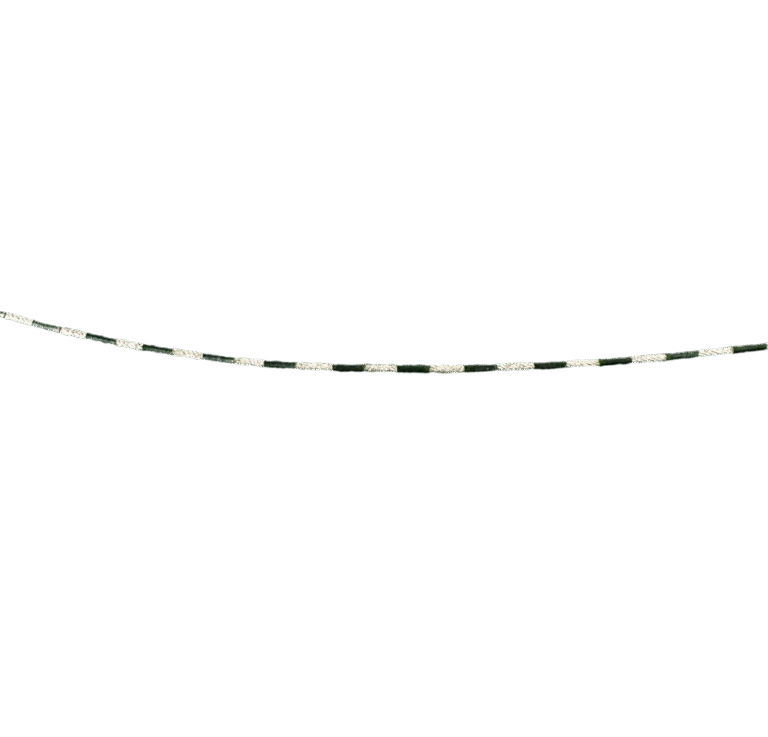

Today, industries are growing fast. This makes precision very important. Cutting glass and ceramics by hand can be hard. An industrial prism cutting machine helps. It cuts materials perfectly and consistently produces smooth edges. These machines are used for optical glass cutting for cameras, microscopes, and lenses. They are also used for ceramic prism cutting in electronics and science. With Diamond Wire Saw technology and intelligent controls, these machines operate quickly and accurately. They are safe, reliable, and valuable for manufacturers, researchers, and hobbyists. Importance of Industrial Prism Cutting Machines Cutting glass or ceramics by hand is a challenging task. You can break the material or make uneven edges. An industrial prism cutting machine solves this problem. It gives perfect edges every time. These machines are utilized in various applications. For example, optical-glass cutting machines are used to produce prisms, lenses, and mirrors. They are used in cameras, microscopes, telescopes,