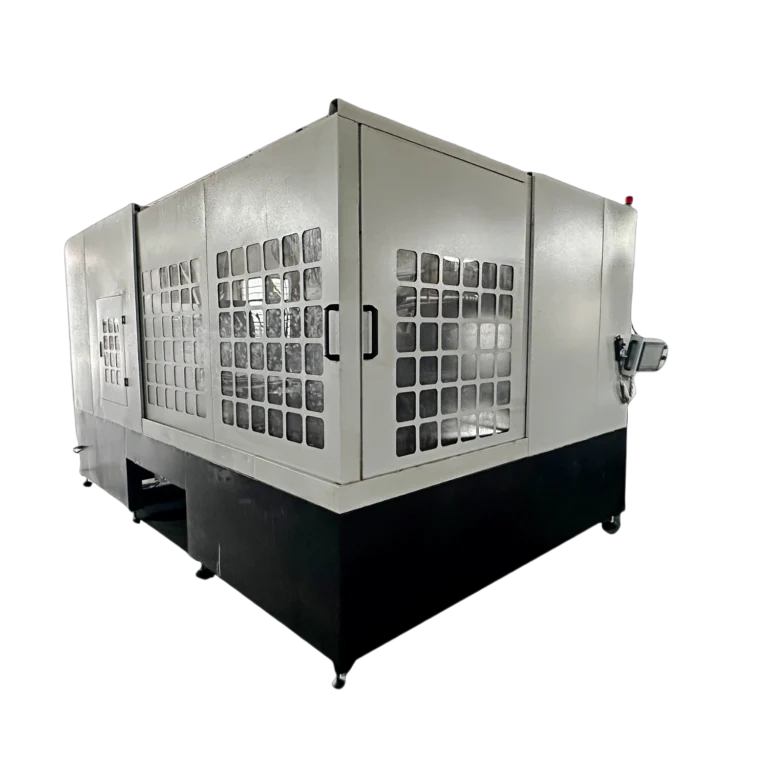

Choosing the Best Horizontal Diamond Wire Cutting Machine

A Horizontal Diamond Wire Cutting Machine is constructive for cutting hard materials. It can cut quartz, optical glass, graphite, and aerospace parts. This machine makes cutting fast, easy, and exact. It saves material and reduces waste. It also helps create smooth and perfect products. Reliable and secure machinery is essential for factories and workshops. When working with big and bulky materials, using the proper equipment may save time, minimize errors, and simplify the process. Every company that wants good quality products should choose the right machine carefully. Horizontal Diamond Wire Cutting Machine for Precise Cuts A horizontal diamond wire cutting machine is a machine that uses a wire covered with tiny diamonds. The wire moves sideways and cuts materials smoothly. The diamonds make the cuts clean and exact. This machine is superior to regular saws because it produces less dust and waste. It is used in quartz cutting, optical glass