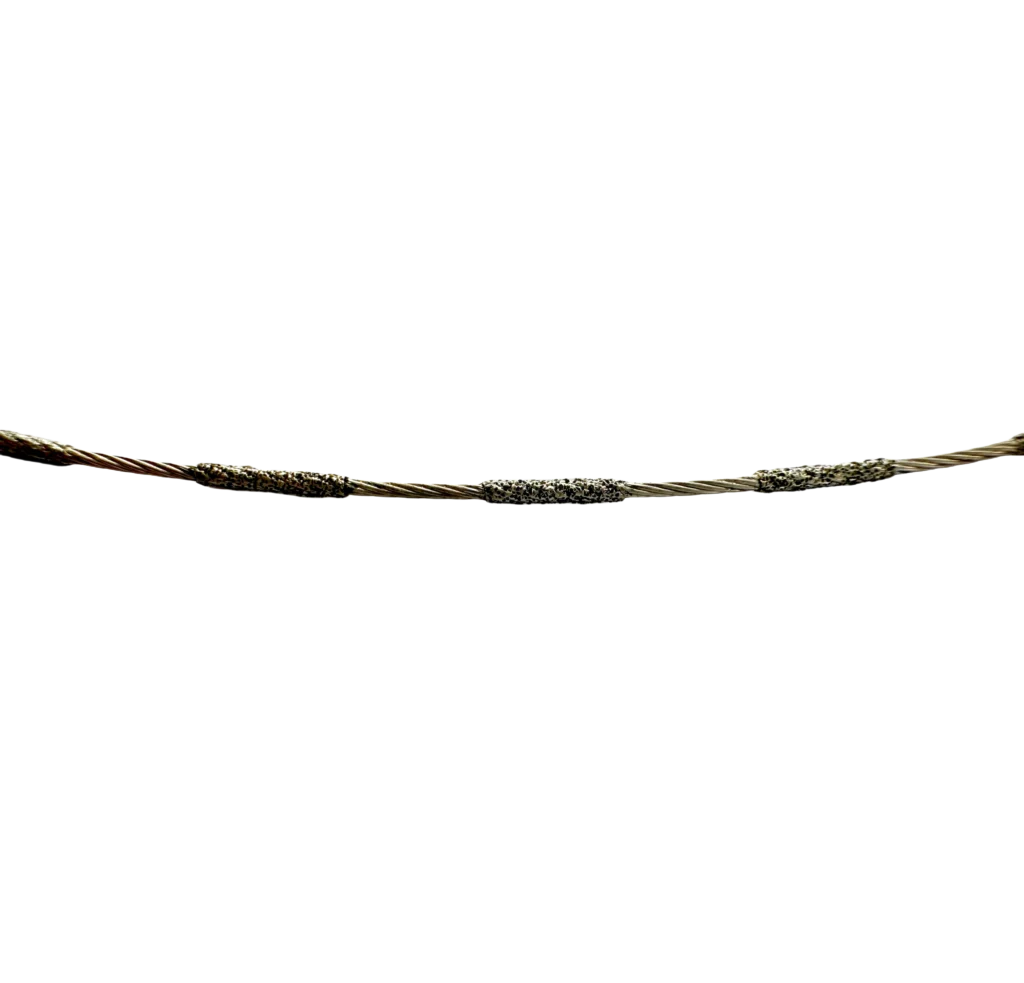

Segment-Coated Quartz Wire Saw

The Segment-Coated Diamond Wire Loop features a unique interval (segmental) electroplated coating, leaving intentional non-coated gaps between abrasive sections. This design creates built-in chip evacuation zones that significantly improve cutting stability and surface quality when processing high-dust materials like graphite, sintered ceramics, and foamed glass.

The segmented structure reduces wire clogging, heat accumulation, and energy loss—making it ideal for clean, long-duration slicing applications.

KEY FEATURES

1. Spaced Coating for Better Chip Discharge

Alternating diamond-coated and uncoated segments allow debris to escape during cutting, preventing wire loading and ensuring smoother feed.

2. Designed for Powder-Generating Materials

Best suited for slicing graphite, ceramic green bodies, and porous brittle substrates that typically clog fully-coated wires.

3. Enhanced Wire Life & Thermal Stability

The reduced abrasive contact area lowers friction and heat buildup, extending wire longevity during continuous operation.

4. Stable Kerf & Smooth Surface Quality

Delivers narrow kerf width (typically 0.6–1.2 mm) while reducing edge damage on dusty, fragile materials.

5. Custom Lengths & Diameters Available

Offered in diameters from 0.8 mm to 2.5 mm, with loop lengths tailored for various endless wire saws.

TECHNICAL SPECIFICATION

| Wire Diameter | Coating Type | Working Tension (N) | Breaking Tension (N) | Recommended Length | Application Examples |

|---|---|---|---|---|---|

| 0.80 mm | Segmental | 51 | 210 | 1M – 10M | Green ceramics, porous glass |

| 1.00 mm | Segmental | 60 | 250 | 1M – 10M | Graphite blocks, foam glass |

| 1.50 mm | Segmental | 72 | 340 | 2M – 12M | Sintered ceramic molds |

| 2.00 mm | Segmental | 110 | 480 | 2M – 15M | High-density graphite or alumina |

| 2.50 mm | Segmental | 138 | 550 | 2M – 15M | Large graphite plates |

3 Different Types of Electroplated Diamond Wire loop

The difference between different Electroplated Diamond Wire Loop

- Full-Coated Electroplated Diamond Wire Loop:

- The cutting wire of full-coated wires is relatively thin, with the thinnest being 0.3 mm.

- These wires are particularly advantageous in cutting hard and brittle materials such as quartz, silicon rods, optical glass, and rare metals.

- These wires are particularly advantageous in cutting hard and brittle materials such as quartz, silicon rods, optical glass, and rare metals.

- The fully coated wire has a large number of diamond abrasives all over the surface of the cutting wire, so it has a strong cutting force. Therefore, it has obvious advantages when cutting materials with small chip removal and high hardness.

- Our fully coated wire not only has a high abrasive density, but also uses a mixture of raw diamonds and crushed diamonds, making the cutting wire both sharp and wear-resistant. Therefore, the service life is longer than others.

- Segmented-Coated Electroplated Diamond Wire Loop:

- The thinnest segmented-coated wire is 0.8mm.

- The segmented coating creates a lot space on the surface of the cutting wire, which can accommodate a large amount of material debris during the cutting process. As the cutting wire moves, it carries and discharges the debris, significantly increasing its chip removal capacity.

- These wires excel in cutting materials like graphite and corrugated paper, which are not very hard but produce a lot of dust.

- Thread- Coated Electroplated Diamond Wire Loop:

- The thinnest thread-coated wire is 0.5 mm.

- The threaded coating creates spiral gaps on the surface of the diamond wire, which can accommodate a large amount of material debris during the rotation of the cutting wire. As the cutting wire moves, it carries and discharges the debris, significantly increasing its chip removal capacity.

- These wires excel in cutting materials like graphite and corrugated paper, which are not very hard but produce a lot of dust.

Additionally, full-coated Electroplated Diamond Wire Loop are widely used in materials processing where cutting fluid can be applied, whereas segmented-coated and thread- coated diamond wires are mainly used in dry cutting processes.

HOW ELECTROPLATED DIAMONDWIRE LOOP LOOKS

THE MATERIAL ELECTROPLATED DIAMOND WIRE LOOP CUT

Optical Glass Cutting

Filters, Domes, Prism Blanks

Sapphire

Ingot and Wafer Slicing

Fused Quartz and Silica

Component Production

Magnetic Ceramic

Material Cutting

Silicon

Compound Semiconductor Wafer Processing

Customer Testimonials

Frequently Asked Questions

What materials can I cut with an endless diamond wire saw?

How can I use an endless diamond wire loop saw?

You need a wire saw machine which can tention the cutting wire.buy one or manully make one.

What is the serving life of an endless diamond wire saw?

What is the wire length?

If the wire breaks, can it be reconnected and used again?

How Can I buy the diamond wire loop?

Let us konow your required wire dia and wire length, we will send the diamond wire loop to your location by DHL or Fedex.